| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 5023079 | 1470245 | 2018 | 12 صفحه PDF | دانلود رایگان |

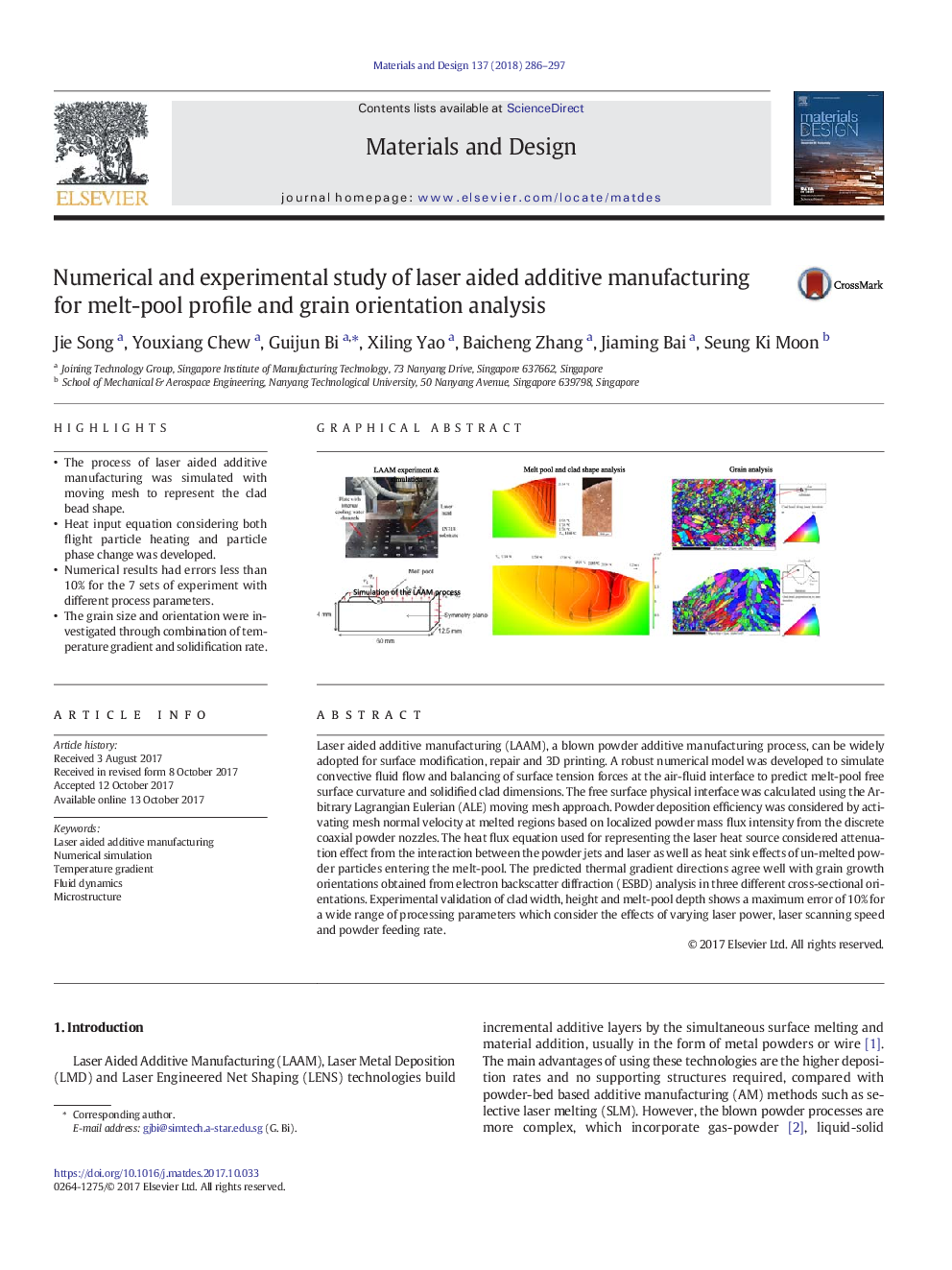

- The process of laser aided additive manufacturing was simulated with moving mesh to represent the clad bead shape.

- Heat input equation considering both flight particle heating and particle phase change was developed.

- Numerical results had errors less than 10% for the 7 sets of experiment with different process parameters.

- The grain size and orientation were investigated through combination of temperature gradient and solidification rate.

Laser aided additive manufacturing (LAAM), a blown powder additive manufacturing process, can be widely adopted for surface modification, repair and 3D printing. A robust numerical model was developed to simulate convective fluid flow and balancing of surface tension forces at the air-fluid interface to predict melt-pool free surface curvature and solidified clad dimensions. The free surface physical interface was calculated using the Arbitrary Lagrangian Eulerian (ALE) moving mesh approach. Powder deposition efficiency was considered by activating mesh normal velocity at melted regions based on localized powder mass flux intensity from the discrete coaxial powder nozzles. The heat flux equation used for representing the laser heat source considered attenuation effect from the interaction between the powder jets and laser as well as heat sink effects of un-melted powder particles entering the melt-pool. The predicted thermal gradient directions agree well with grain growth orientations obtained from electron backscatter diffraction (ESBD) analysis in three different cross-sectional orientations. Experimental validation of clad width, height and melt-pool depth shows a maximum error of 10% for a wide range of processing parameters which consider the effects of varying laser power, laser scanning speed and powder feeding rate.

315

Journal: Materials & Design - Volume 137, 5 January 2018, Pages 286-297