| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6474884 | 1424971 | 2017 | 8 صفحه PDF | دانلود رایگان |

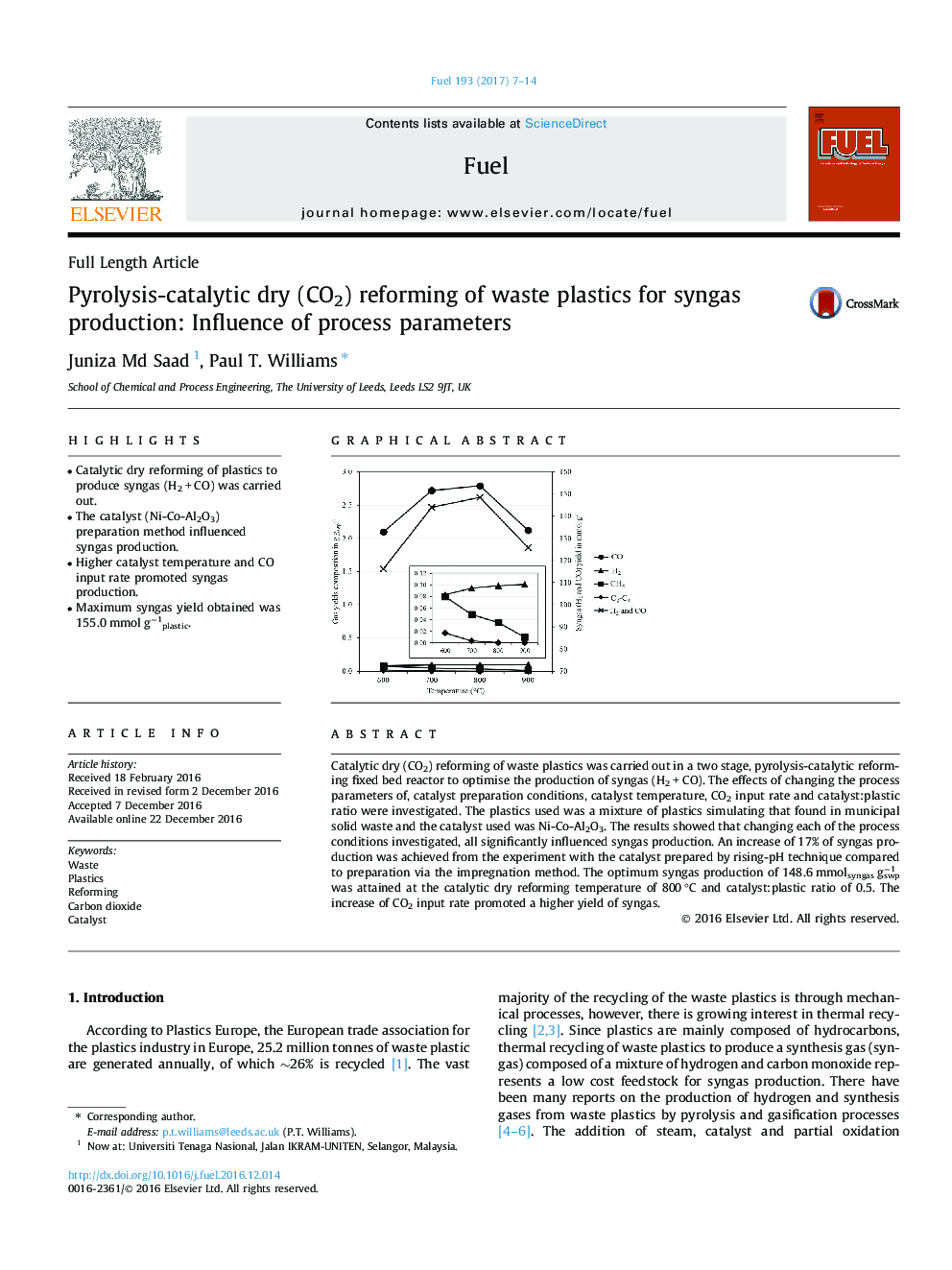

- Catalytic dry reforming of plastics to produce syngas (H2Â +Â CO) was carried out.

- The catalyst (Ni-Co-Al2O3) preparation method influenced syngas production.

- Higher catalyst temperature and CO input rate promoted syngas production.

- Maximum syngas yield obtained was 155.0 mmol gâ1plastic.

Catalytic dry (CO2) reforming of waste plastics was carried out in a two stage, pyrolysis-catalytic reforming fixed bed reactor to optimise the production of syngas (H2 + CO). The effects of changing the process parameters of, catalyst preparation conditions, catalyst temperature, CO2 input rate and catalyst:plastic ratio were investigated. The plastics used was a mixture of plastics simulating that found in municipal solid waste and the catalyst used was Ni-Co-Al2O3. The results showed that changing each of the process conditions investigated, all significantly influenced syngas production. An increase of 17% of syngas production was achieved from the experiment with the catalyst prepared by rising-pH technique compared to preparation via the impregnation method. The optimum syngas production of 148.6 mmolsyngas gâ1swp was attained at the catalytic dry reforming temperature of 800 °C and catalyst:plastic ratio of 0.5. The increase of CO2 input rate promoted a higher yield of syngas.

114

Journal: Fuel - Volume 193, 1 April 2017, Pages 7-14