| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10672893 | CIRP Annals - Manufacturing Technology | 2016 | 4 Pages |

Abstract

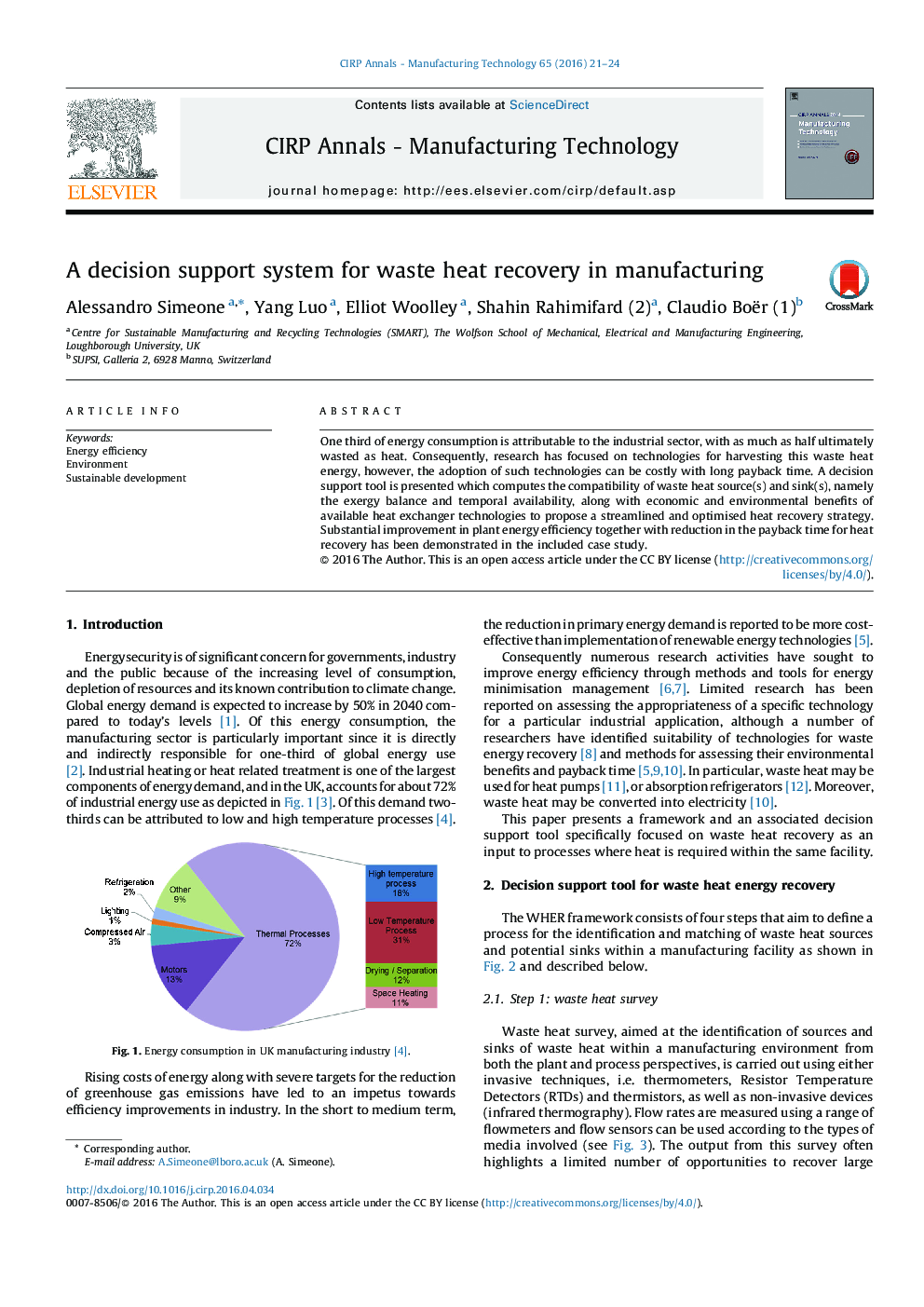

One third of energy consumption is attributable to the industrial sector, with as much as half ultimately wasted as heat. Consequently, research has focused on technologies for harvesting this waste heat energy, however, the adoption of such technologies can be costly with long payback time. A decision support tool is presented which computes the compatibility of waste heat source(s) and sink(s), namely the exergy balance and temporal availability, along with economic and environmental benefits of available heat exchanger technologies to propose a streamlined and optimised heat recovery strategy. Substantial improvement in plant energy efficiency together with reduction in the payback time for heat recovery has been demonstrated in the included case study.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Alessandro Simeone, Yang Luo, Elliot Woolley, Shahin Rahimifard, Claudio Boër,