| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10672904 | CIRP Annals - Manufacturing Technology | 2016 | 4 Pages |

Abstract

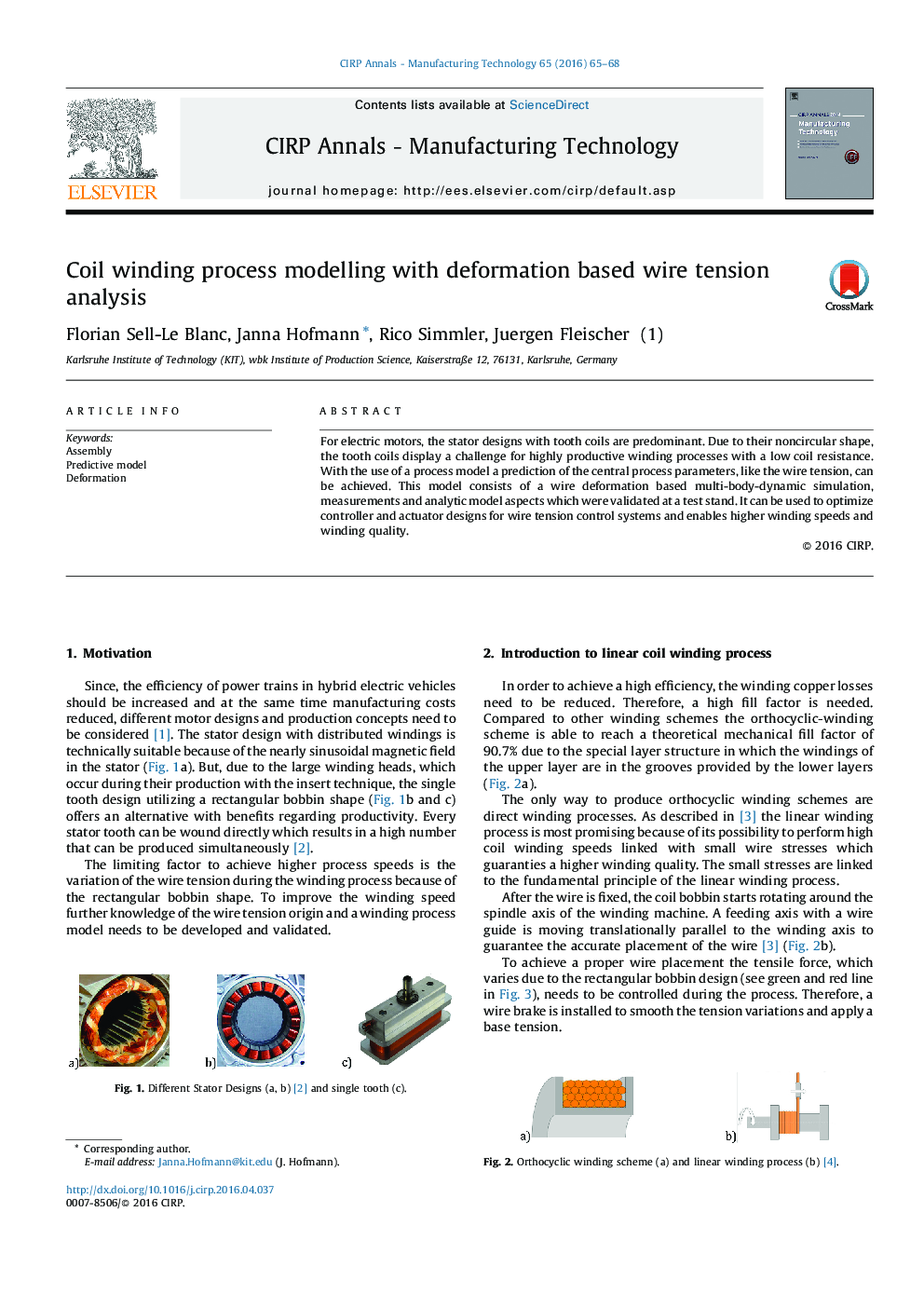

For electric motors, the stator designs with tooth coils are predominant. Due to their noncircular shape, the tooth coils display a challenge for highly productive winding processes with a low coil resistance. With the use of a process model a prediction of the central process parameters, like the wire tension, can be achieved. This model consists of a wire deformation based multi-body-dynamic simulation, measurements and analytic model aspects which were validated at a test stand. It can be used to optimize controller and actuator designs for wire tension control systems and enables higher winding speeds and winding quality.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Florian Sell-Le Blanc, Janna Hofmann, Rico Simmler, Juergen Fleischer,