| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10672942 | CIRP Annals - Manufacturing Technology | 2016 | 4 Pages |

Abstract

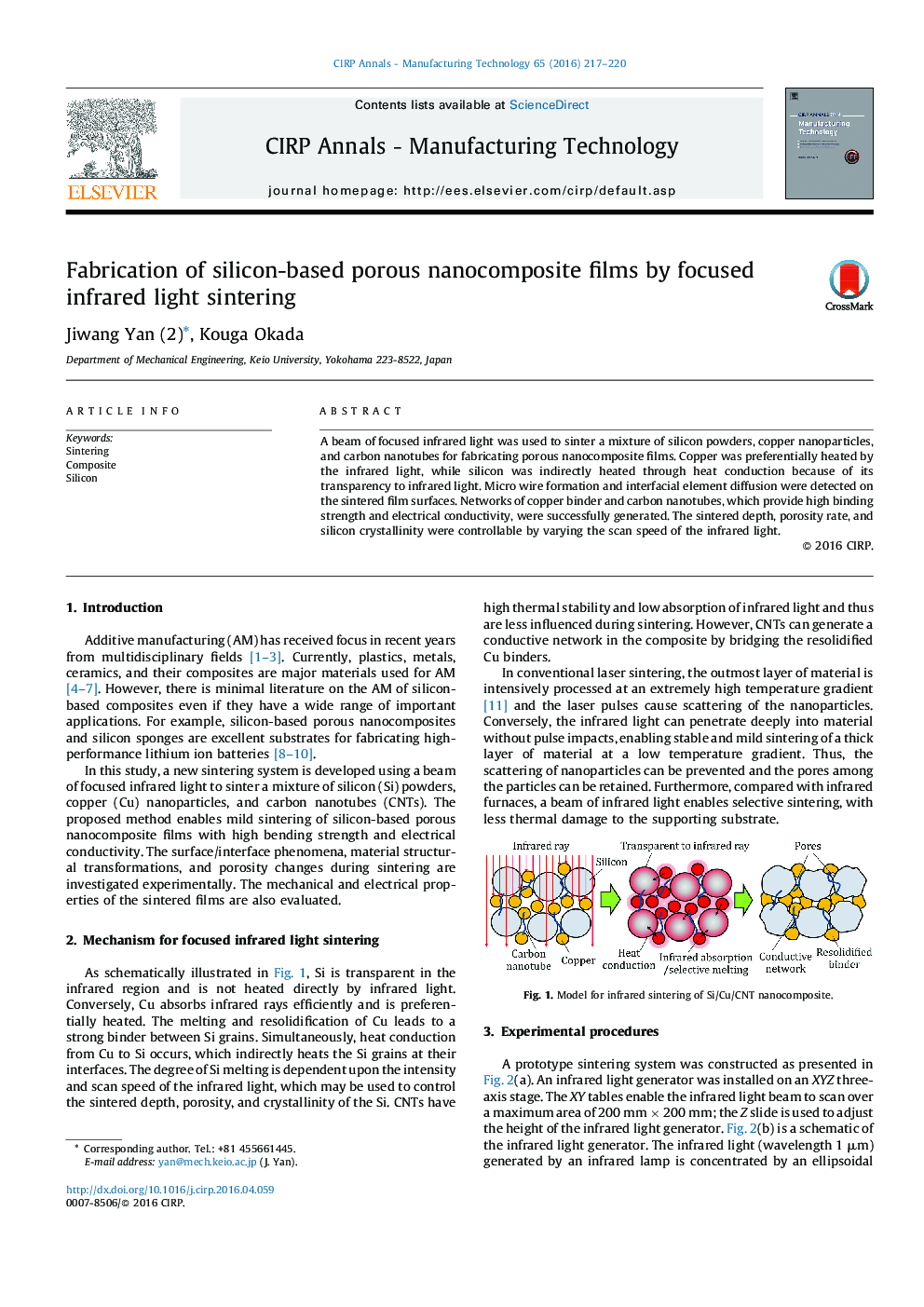

A beam of focused infrared light was used to sinter a mixture of silicon powders, copper nanoparticles, and carbon nanotubes for fabricating porous nanocomposite films. Copper was preferentially heated by the infrared light, while silicon was indirectly heated through heat conduction because of its transparency to infrared light. Micro wire formation and interfacial element diffusion were detected on the sintered film surfaces. Networks of copper binder and carbon nanotubes, which provide high binding strength and electrical conductivity, were successfully generated. The sintered depth, porosity rate, and silicon crystallinity were controllable by varying the scan speed of the infrared light.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Jiwang Yan, Kouga Okada,