| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10672967 | CIRP Annals - Manufacturing Technology | 2016 | 4 Pages |

Abstract

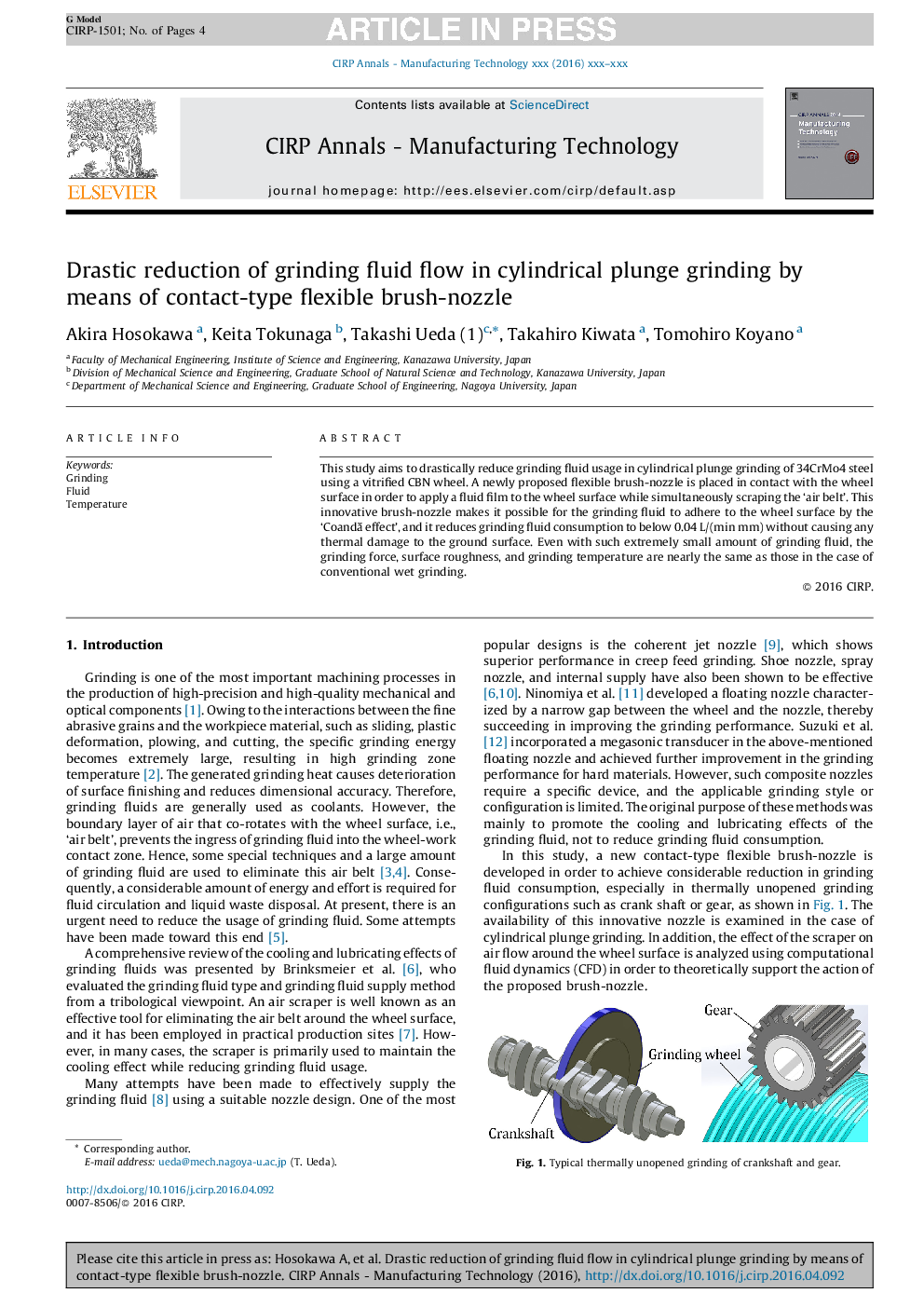

This study aims to drastically reduce grinding fluid usage in cylindrical plunge grinding of 34CrMo4 steel using a vitrified CBN wheel. A newly proposed flexible brush-nozzle is placed in contact with the wheel surface in order to apply a fluid film to the wheel surface while simultaneously scraping the 'air belt'. This innovative brush-nozzle makes it possible for the grinding fluid to adhere to the wheel surface by the 'CoandÄ effect', and it reduces grinding fluid consumption to below 0.04 L/(min mm) without causing any thermal damage to the ground surface. Even with such extremely small amount of grinding fluid, the grinding force, surface roughness, and grinding temperature are nearly the same as those in the case of conventional wet grinding.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Akira Hosokawa, Keita Tokunaga, Takashi Ueda, Takahiro Kiwata, Tomohiro Koyano,