| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673222 | CIRP Annals - Manufacturing Technology | 2009 | 4 Pages |

Abstract

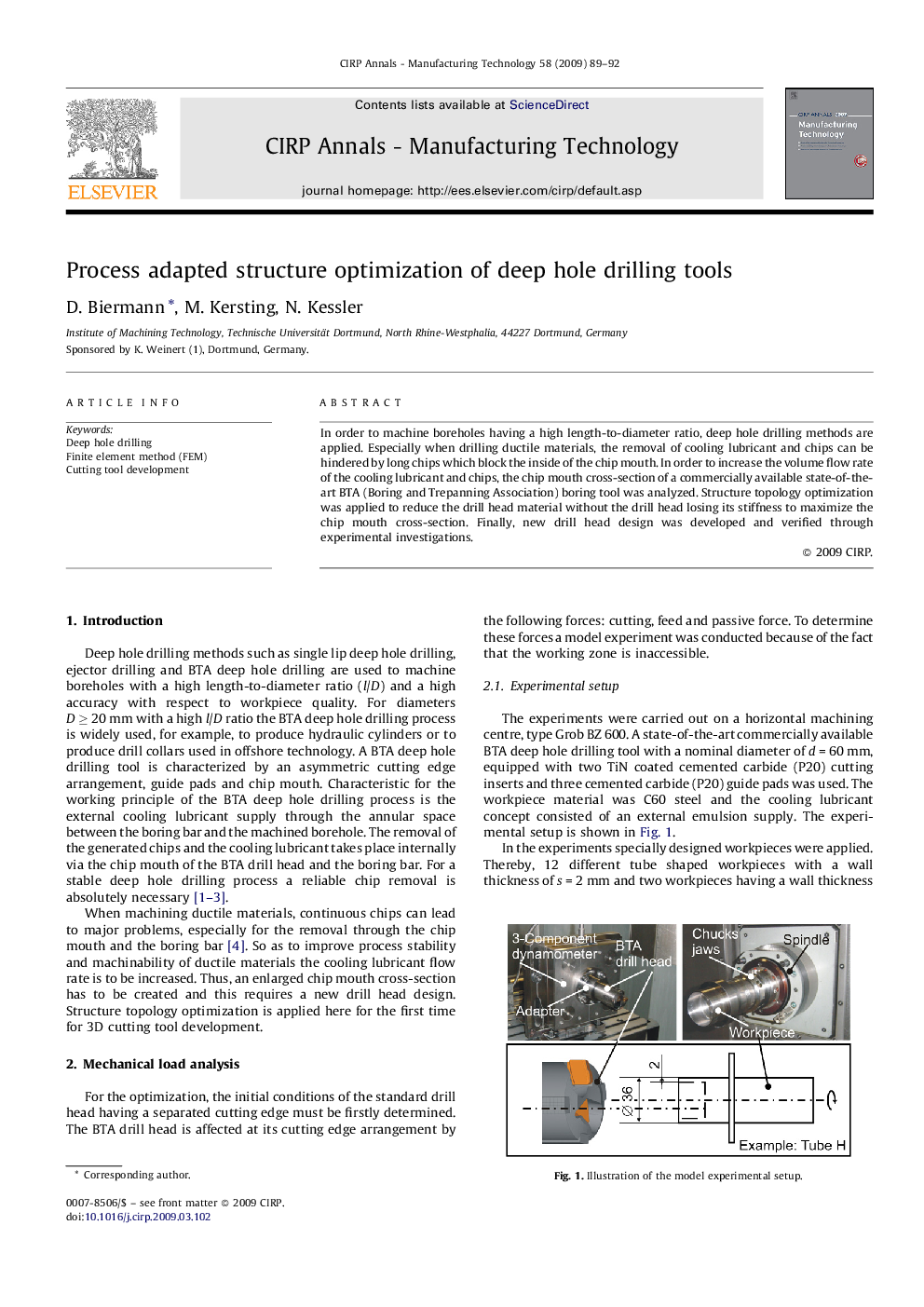

In order to machine boreholes having a high length-to-diameter ratio, deep hole drilling methods are applied. Especially when drilling ductile materials, the removal of cooling lubricant and chips can be hindered by long chips which block the inside of the chip mouth. In order to increase the volume flow rate of the cooling lubricant and chips, the chip mouth cross-section of a commercially available state-of-the-art BTA (Boring and Trepanning Association) boring tool was analyzed. Structure topology optimization was applied to reduce the drill head material without the drill head losing its stiffness to maximize the chip mouth cross-section. Finally, new drill head design was developed and verified through experimental investigations.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

D. Biermann, M. Kersting, N. Kessler,