| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673323 | CIRP Annals - Manufacturing Technology | 2015 | 4 Pages |

Abstract

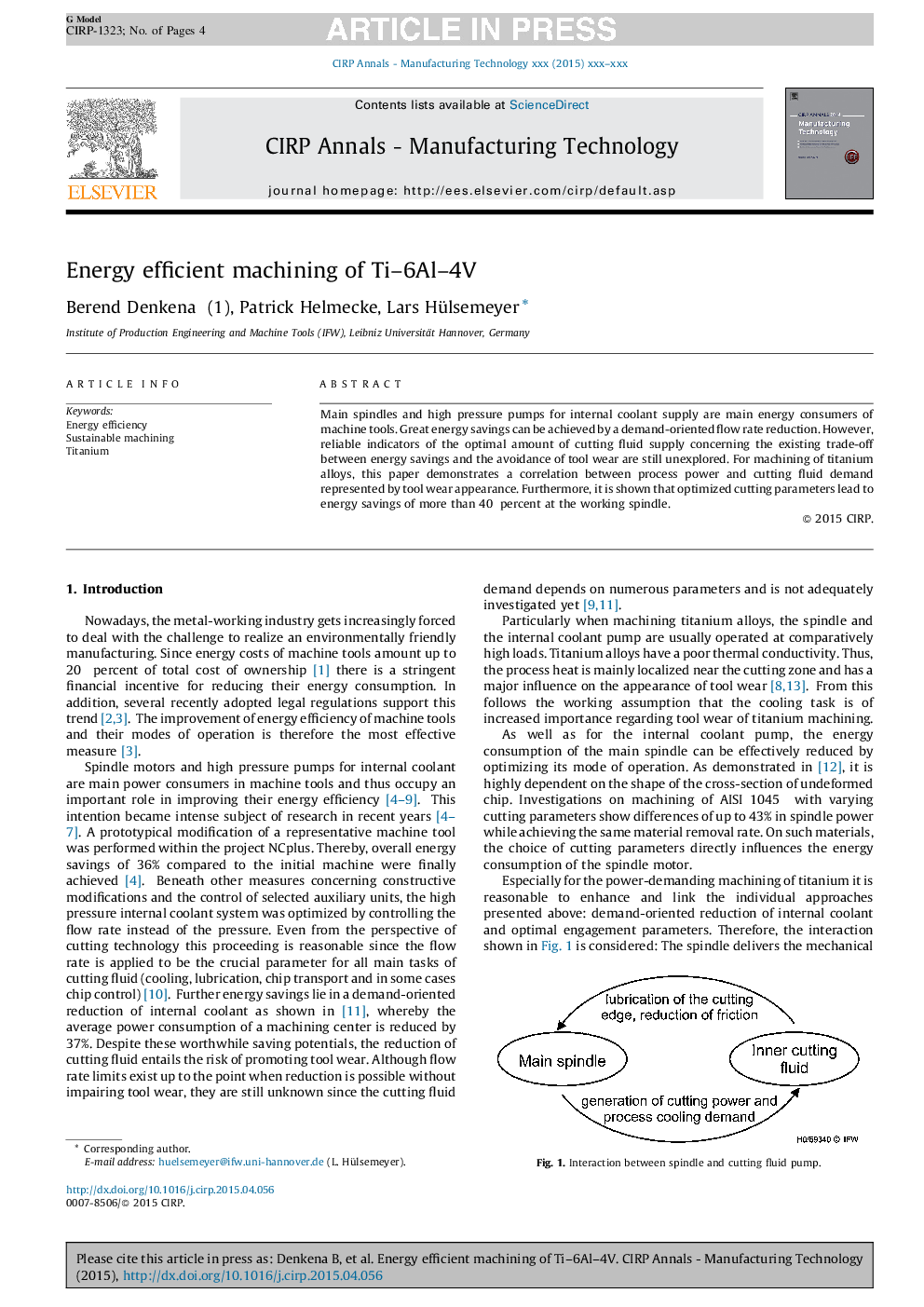

Main spindles and high pressure pumps for internal coolant supply are main energy consumers of machine tools. Great energy savings can be achieved by a demand-oriented flow rate reduction. However, reliable indicators of the optimal amount of cutting fluid supply concerning the existing trade-off between energy savings and the avoidance of tool wear are still unexplored. For machining of titanium alloys, this paper demonstrates a correlation between process power and cutting fluid demand represented by tool wear appearance. Furthermore, it is shown that optimized cutting parameters lead to energy savings of more than 40 percent at the working spindle.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Berend Denkena, Patrick Helmecke, Lars Hülsemeyer,