| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673337 | CIRP Annals - Manufacturing Technology | 2015 | 4 Pages |

Abstract

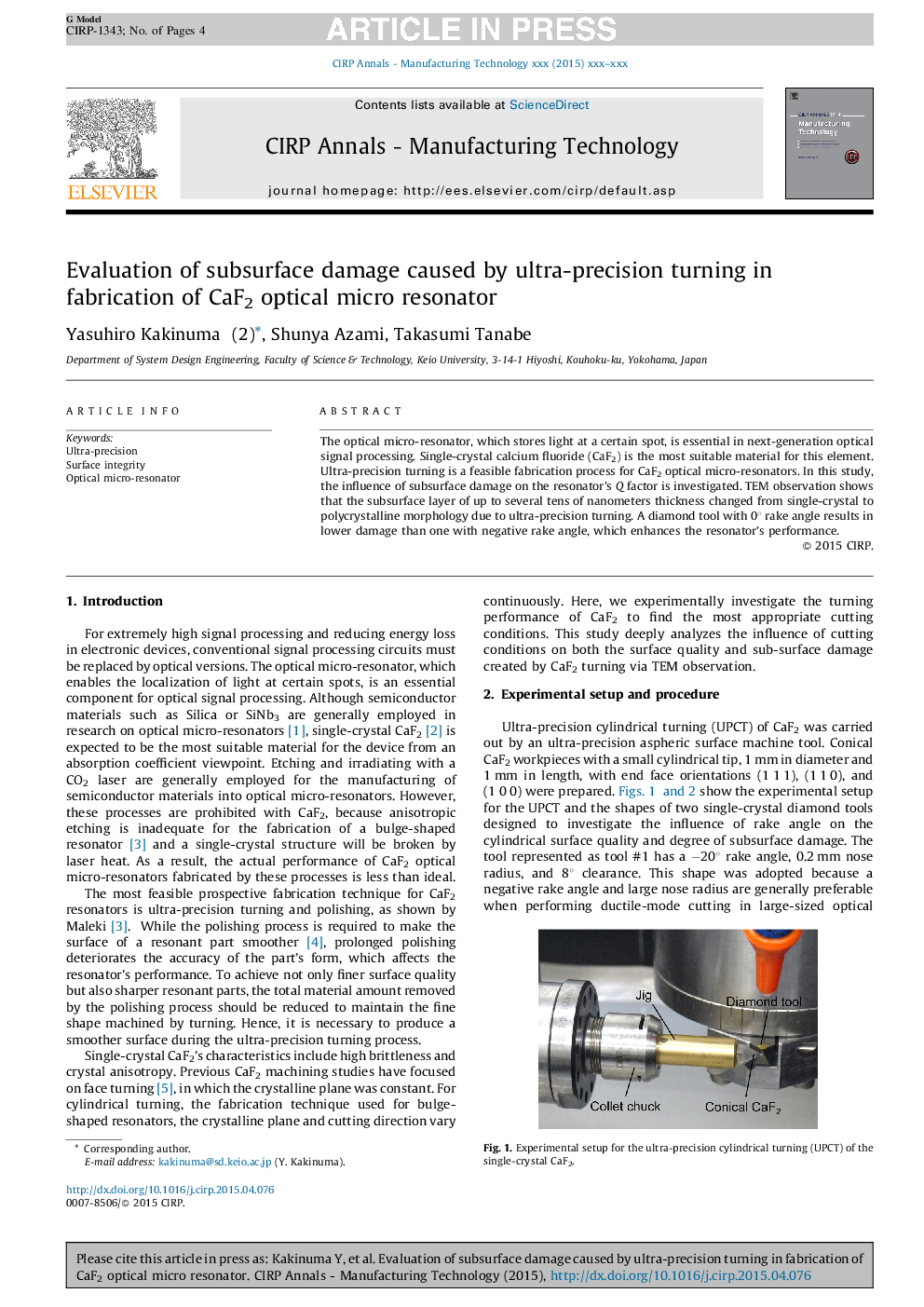

The optical micro-resonator, which stores light at a certain spot, is essential in next-generation optical signal processing. Single-crystal calcium fluoride (CaF2) is the most suitable material for this element. Ultra-precision turning is a feasible fabrication process for CaF2 optical micro-resonators. In this study, the influence of subsurface damage on the resonator's Q factor is investigated. TEM observation shows that the subsurface layer of up to several tens of nanometers thickness changed from single-crystal to polycrystalline morphology due to ultra-precision turning. A diamond tool with 0° rake angle results in lower damage than one with negative rake angle, which enhances the resonator's performance.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Yasuhiro Kakinuma, Shunya Azami, Takasumi Tanabe,