| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673383 | CIRP Annals - Manufacturing Technology | 2015 | 4 Pages |

Abstract

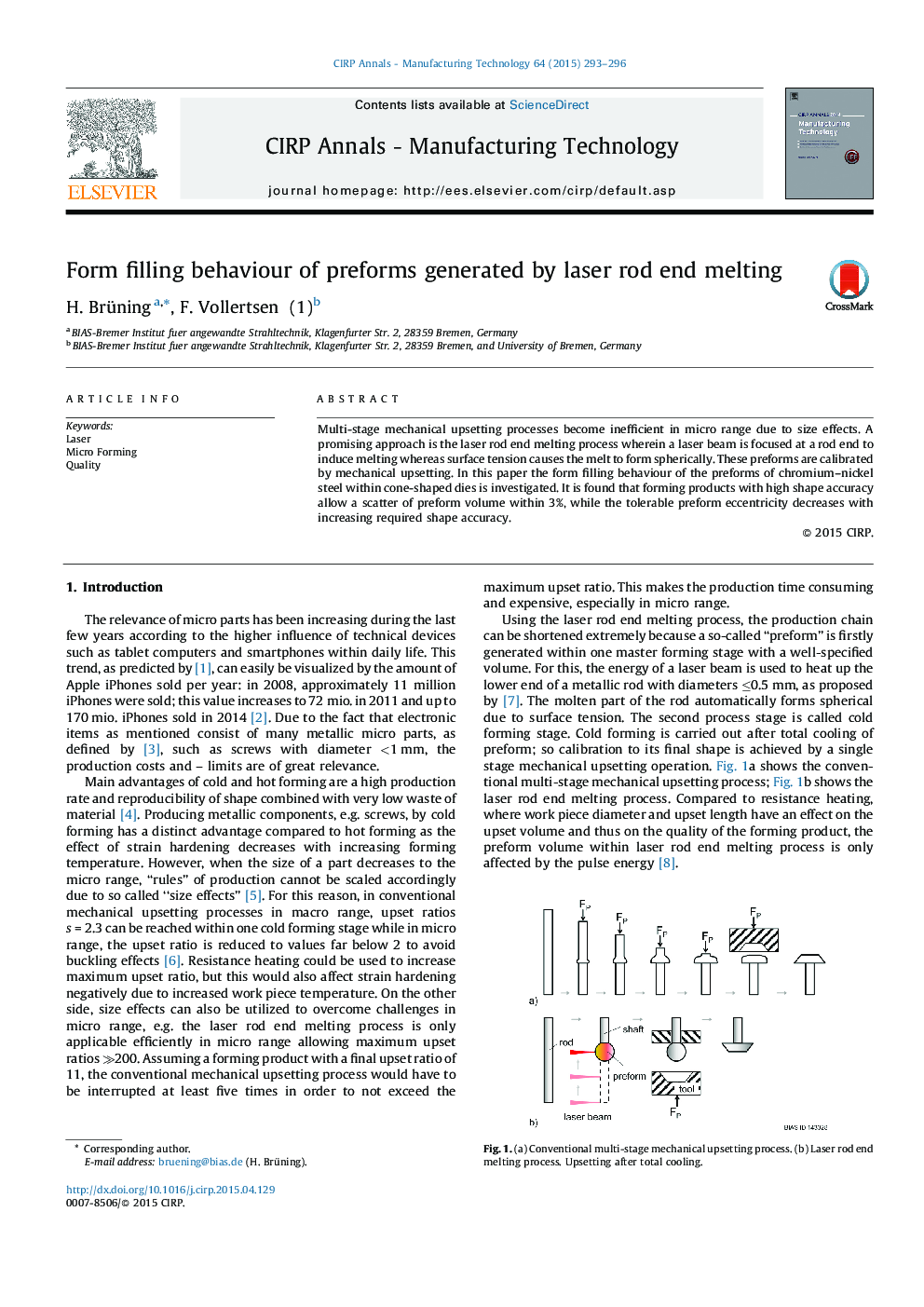

Multi-stage mechanical upsetting processes become inefficient in micro range due to size effects. A promising approach is the laser rod end melting process wherein a laser beam is focused at a rod end to induce melting whereas surface tension causes the melt to form spherically. These preforms are calibrated by mechanical upsetting. In this paper the form filling behaviour of the preforms of chromium-nickel steel within cone-shaped dies is investigated. It is found that forming products with high shape accuracy allow a scatter of preform volume within 3%, while the tolerable preform eccentricity decreases with increasing required shape accuracy.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

H. Brüning, F. Vollertsen,