| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673688 | CIRP Annals - Manufacturing Technology | 2005 | 4 Pages |

Abstract

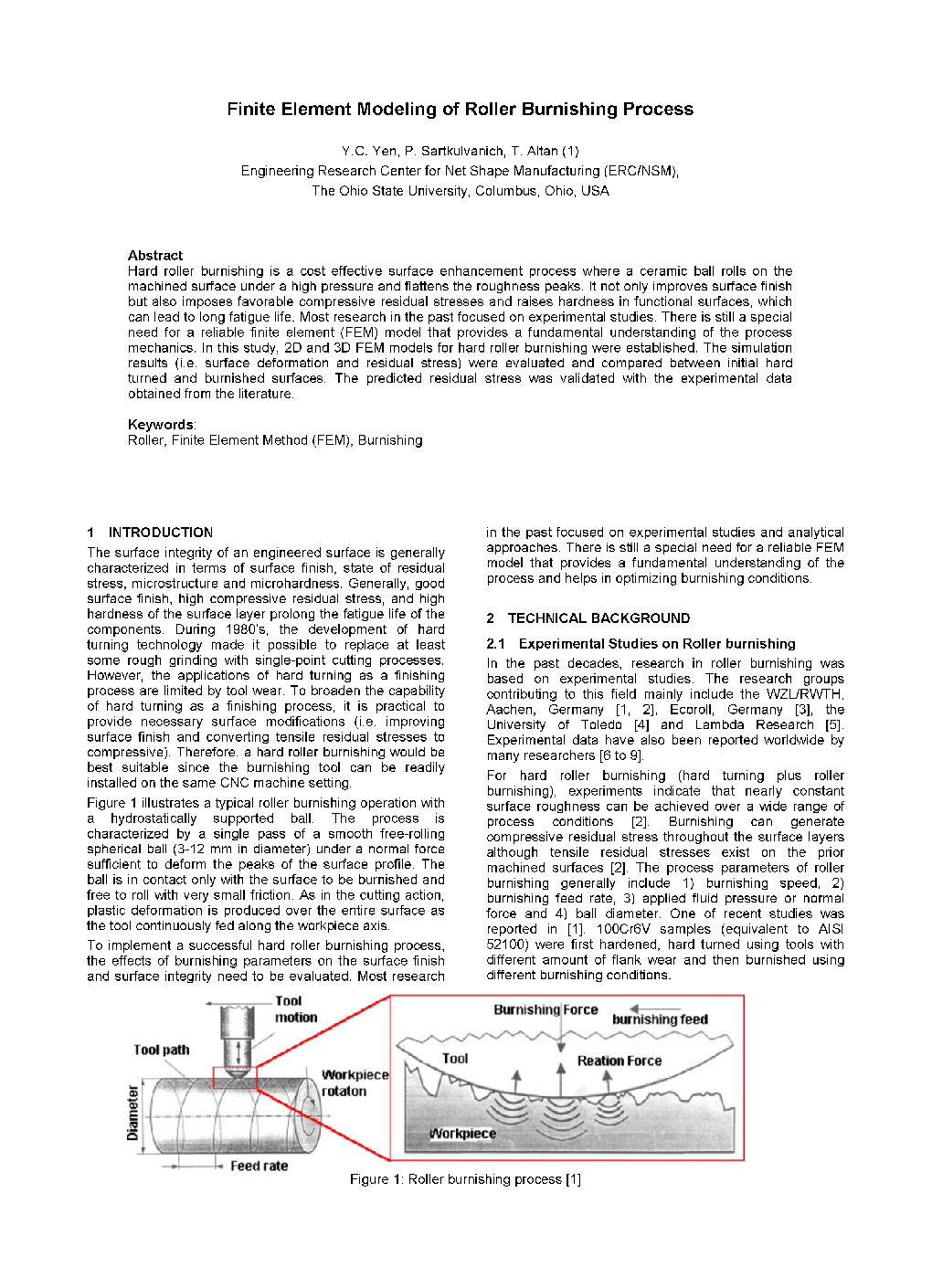

Hard roller burnishing is a cost effective surface enhancement process where a ceramic ball rolls on the machined surface under a high pressure and flattens the roughness peaks. It not only improves surface finish but also imposes favorable compressive residual stresses and raises hardness in functional surfaces, which can lead to long fatigue life. Most research in the past focused on experimental studies. There is still a special need for a reliable finite element (FEM) model that provides a fundamental understanding of the process mechanics. In this study, 2D and 3D FEM models for hard roller burnishing were established. The simulation results (i.e. surface deformation and residual stress) were evaluated and compared between initial hard turned and burnished surfaces. The predicted residual stress was validated with the experimental data obtained from the literature.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Y.C. Yen, P. Sartkulvanich, T. Altan,