| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673690 | CIRP Annals - Manufacturing Technology | 2005 | 4 Pages |

Abstract

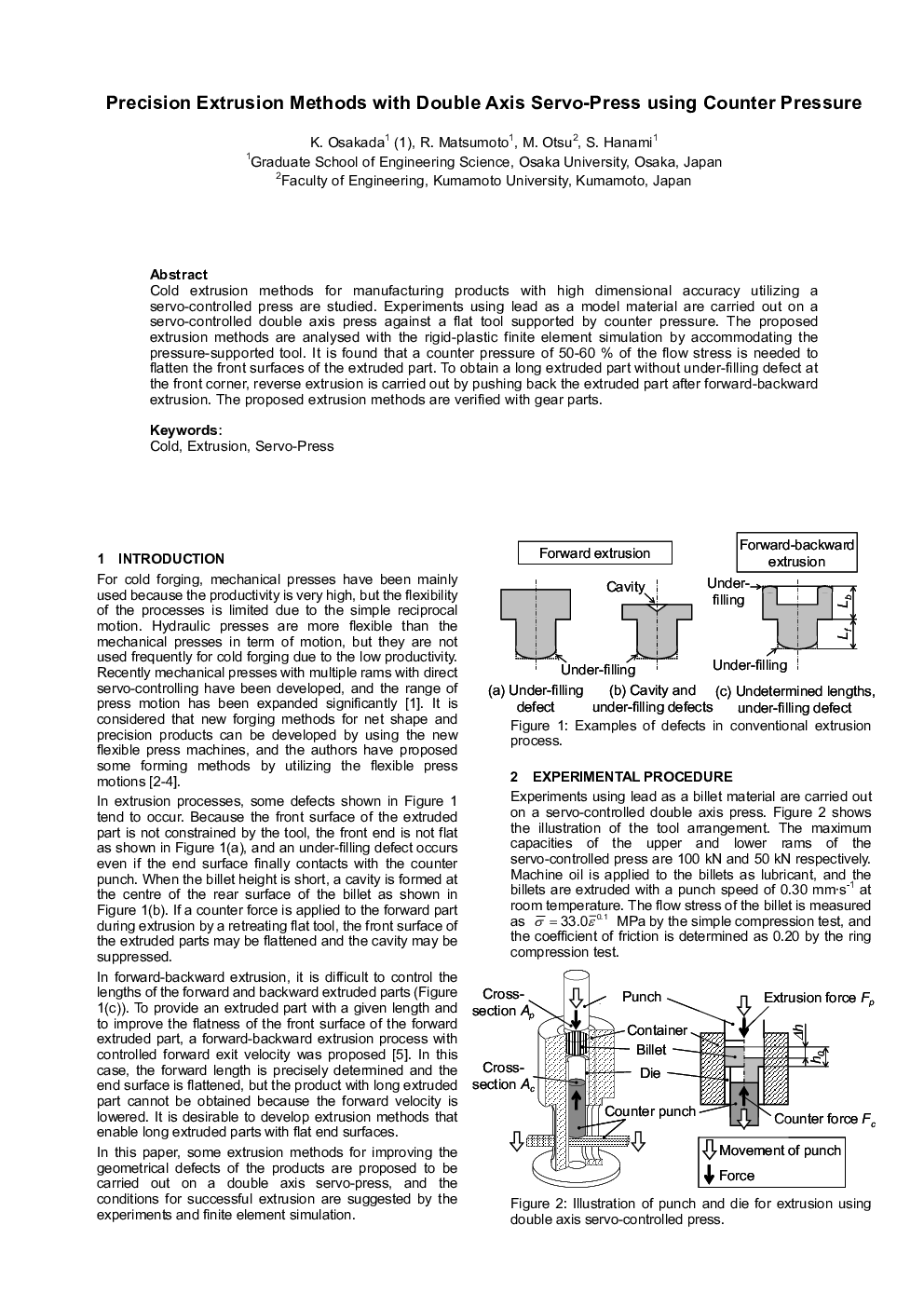

Cold extrusion methods for manufacturing products with high dimensional accuracy utilizing a servo-controlled press are studied. Experiments using lead as a model material are carried out on a servo-controlled double axis press against a flat tool supported by counter pressure. The proposed extrusion methods are analysed with the rigid-plastic finite element simulation by accommodating the pressure-supported tool. It is found that a counter pressure of 50-60 % of the flow stress is needed to flatten the front surfaces of the extruded part. To obtain a long extruded part without under-filling defect at the front corner, reverse extrusion is carried out by pushing back the extruded part after forward-backward extrusion. The proposed extrusion methods are verified with gear parts.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

K. Osakada, R. Matsumoto, M. Otsu, S. Hanami,