| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673699 | CIRP Annals - Manufacturing Technology | 2005 | 4 Pages |

Abstract

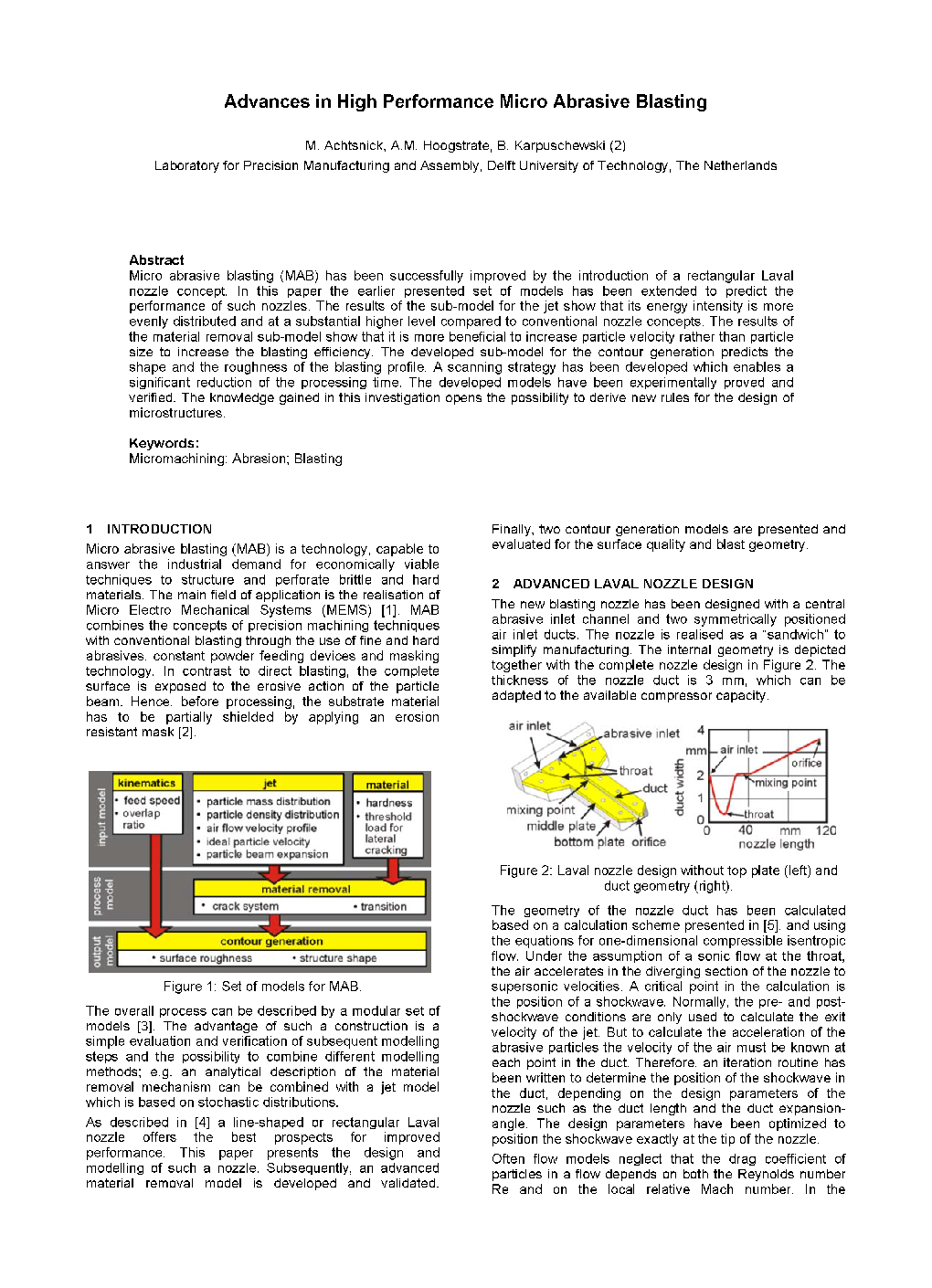

Micro abrasive blasting (MAB) has been successfully improved by the introduction of a rectangular Laval nozzle concept. In this paper the earlier presented set of models has been extended to predict the performance of such nozzles. The results of the sub-model for the jet show that its energy intensity is more evenly distributed and at a substantial higher level compared to conventional nozzle concepts. The results of the material removal sub-model show that it is more beneficial to increase particle velocity rather than particle size to increase the blasting efficiency. The developed sub-model for the contour generation predicts the shape and the roughness of the blasting profile. A scanning strategy has been developed which enables a significant reduction of the processing time. The developed models have been experimentally proved and verified. The knowledge gained in this investigation opens the possibility to derive new rules for the design of microstructures.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

M. Achtsnick, A.M. Hoogstrate, B. Karpuschewski,