| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673702 | CIRP Annals - Manufacturing Technology | 2005 | 4 Pages |

Abstract

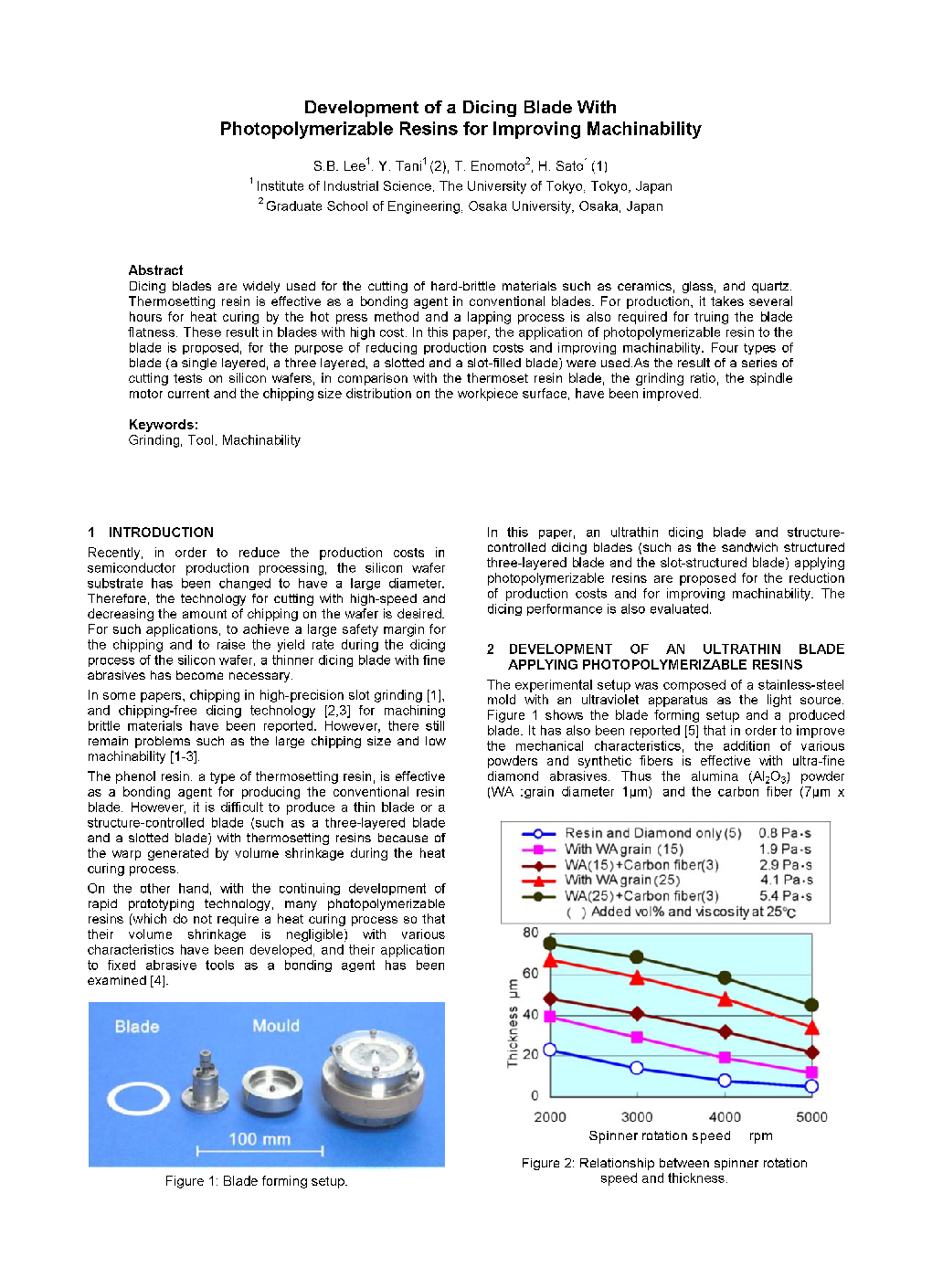

Dicing blades are widely used for the cutting of hard-brittle materials such as ceramics, glass, and quartz. Thermosetting resin is effective as a bonding agent in conventional blades. For production, it takes several hours for heat curing by the hot press method and a lapping process is also required for truing the blade flatness. These result in blades with high cost. In this paper, the application of photopolymerizable resin to the blade is proposed, for the purpose of reducing production costs and improving machinability. Four types of blade (a single layered, a three layered, a slotted and a slot-filled blade) were used. As the result of a series of cutting tests on silicon wafers, in comparison with the thermoset resin blade, the grinding ratio, the spindle motor current and the chipping size distribution on the workpiece surface, have been improved.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

S.B. Lee, Y. Tani, T. Enomoto, H. Sato,