| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10673917 | CIRP Annals - Manufacturing Technology | 2011 | 4 Pages |

Abstract

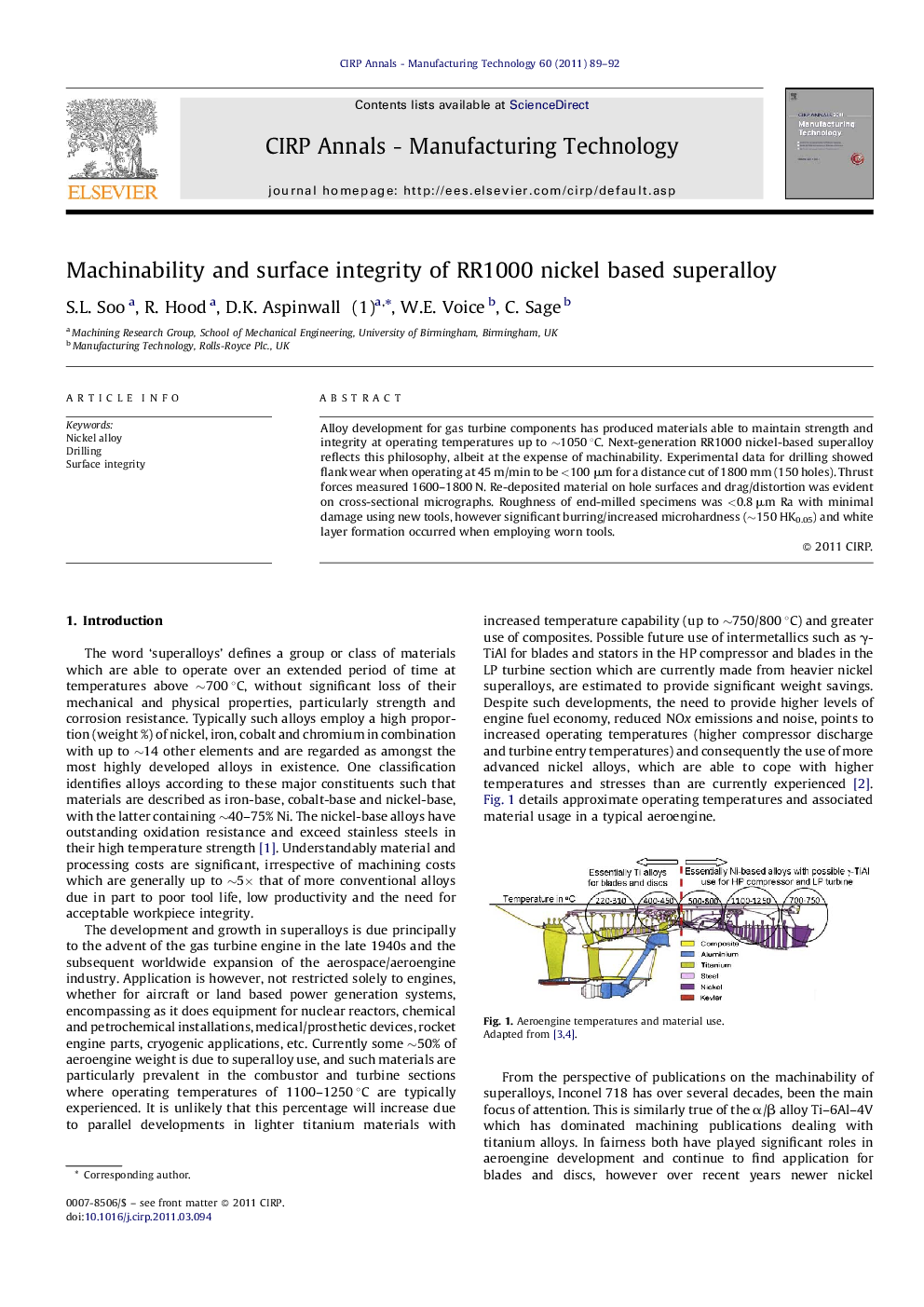

Alloy development for gas turbine components has produced materials able to maintain strength and integrity at operating temperatures up to â¼1050 °C. Next-generation RR1000 nickel-based superalloy reflects this philosophy, albeit at the expense of machinability. Experimental data for drilling showed flank wear when operating at 45 m/min to be <100 μm for a distance cut of 1800 mm (150 holes). Thrust forces measured 1600-1800 N. Re-deposited material on hole surfaces and drag/distortion was evident on cross-sectional micrographs. Roughness of end-milled specimens was <0.8 μm Ra with minimal damage using new tools, however significant burring/increased microhardness (â¼150 HK0.05) and white layer formation occurred when employing worn tools.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

S.L. Soo, R. Hood, D.K. Aspinwall, W.E. Voice, C. Sage,