| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674349 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

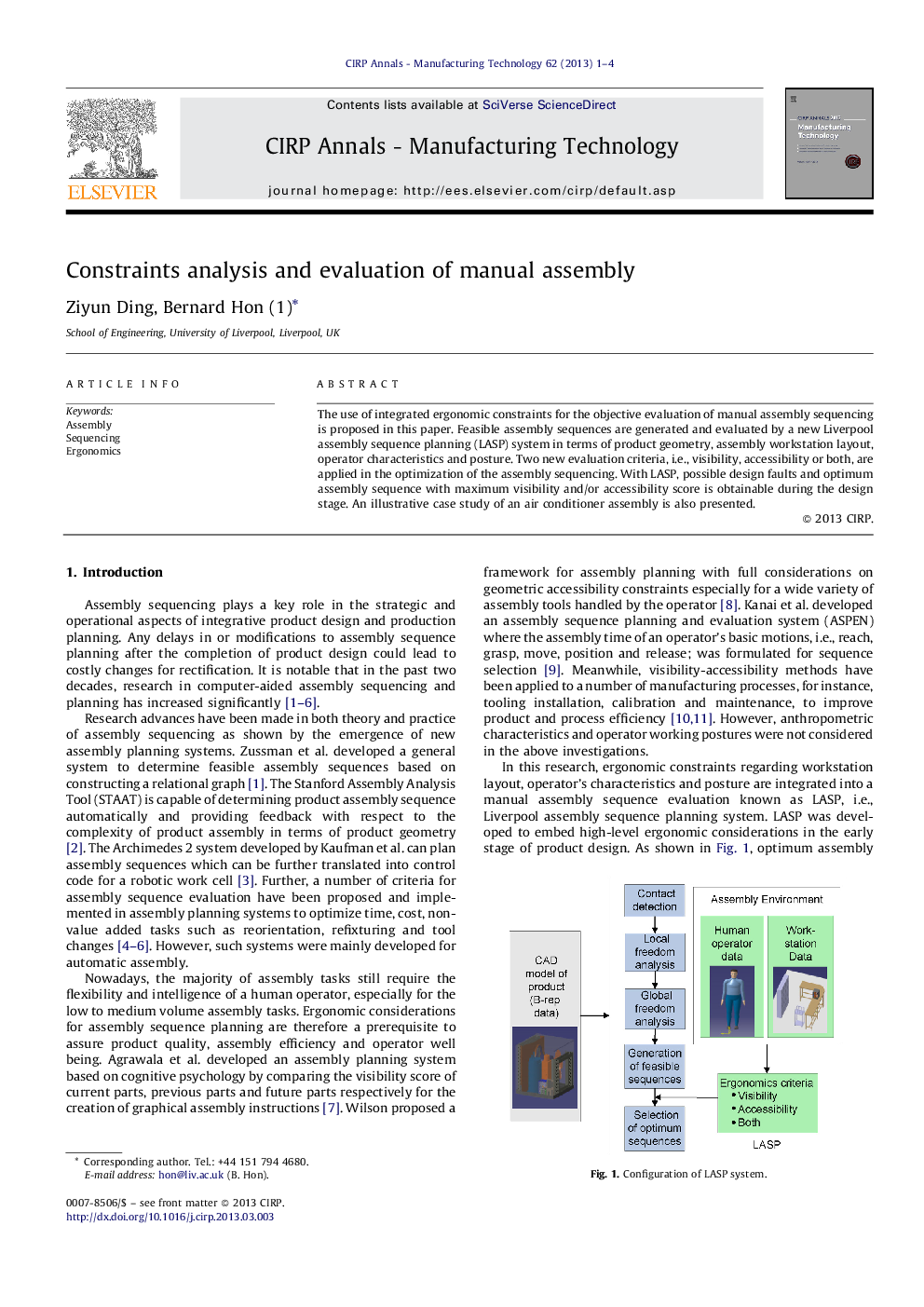

The use of integrated ergonomic constraints for the objective evaluation of manual assembly sequencing is proposed in this paper. Feasible assembly sequences are generated and evaluated by a new Liverpool assembly sequence planning (LASP) system in terms of product geometry, assembly workstation layout, operator characteristics and posture. Two new evaluation criteria, i.e., visibility, accessibility or both, are applied in the optimization of the assembly sequencing. With LASP, possible design faults and optimum assembly sequence with maximum visibility and/or accessibility score is obtainable during the design stage. An illustrative case study of an air conditioner assembly is also presented.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Ziyun Ding, Bernard Hon,