| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674363 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

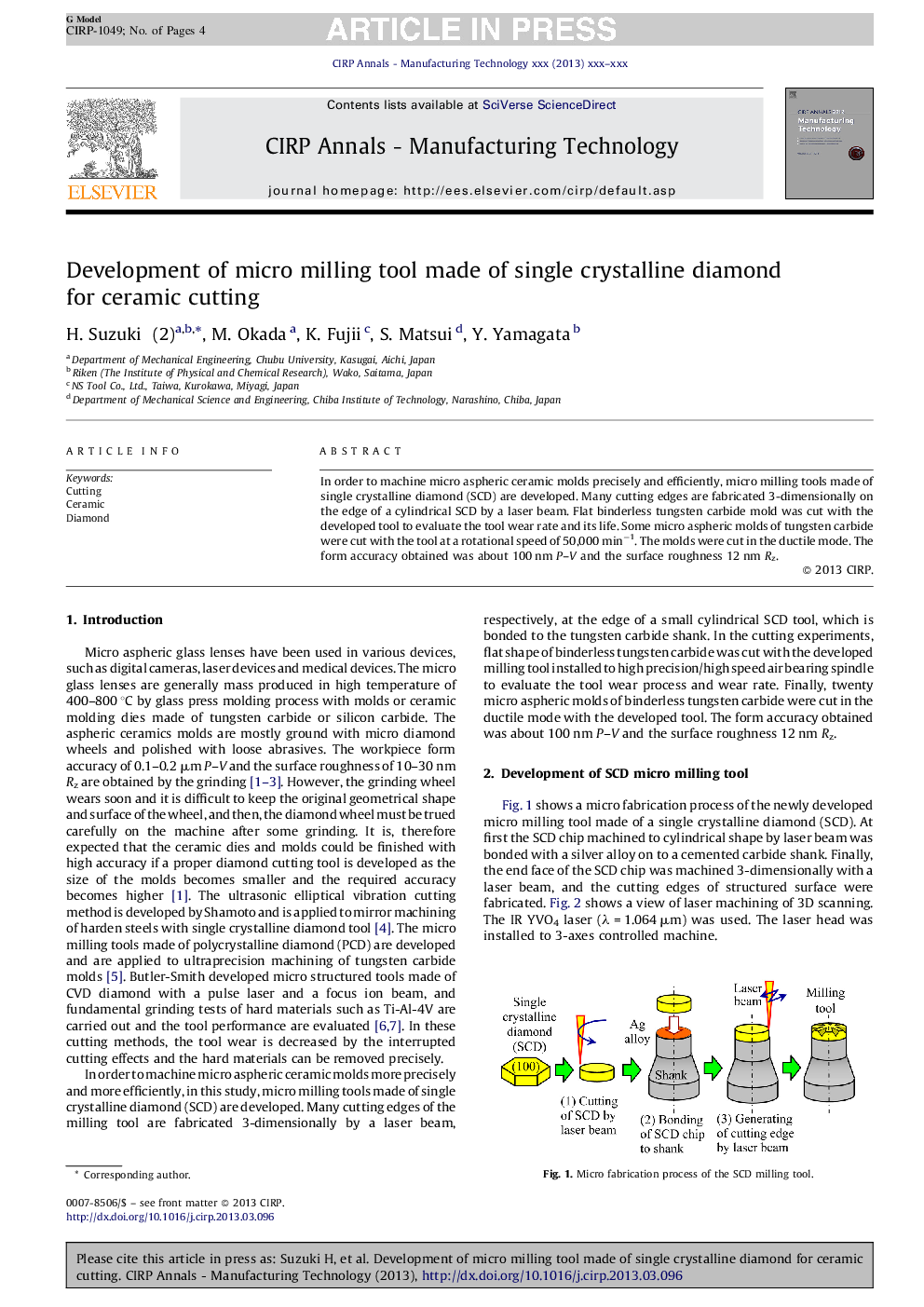

In order to machine micro aspheric ceramic molds precisely and efficiently, micro milling tools made of single crystalline diamond (SCD) are developed. Many cutting edges are fabricated 3-dimensionally on the edge of a cylindrical SCD by a laser beam. Flat binderless tungsten carbide mold was cut with the developed tool to evaluate the tool wear rate and its life. Some micro aspheric molds of tungsten carbide were cut with the tool at a rotational speed of 50,000Â minâ1. The molds were cut in the ductile mode. The form accuracy obtained was about 100Â nm P-V and the surface roughness 12Â nm Rz.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

H. Suzuki, M. Okada, K. Fujii, S. Matsui, Y. Yamagata,