| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674371 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

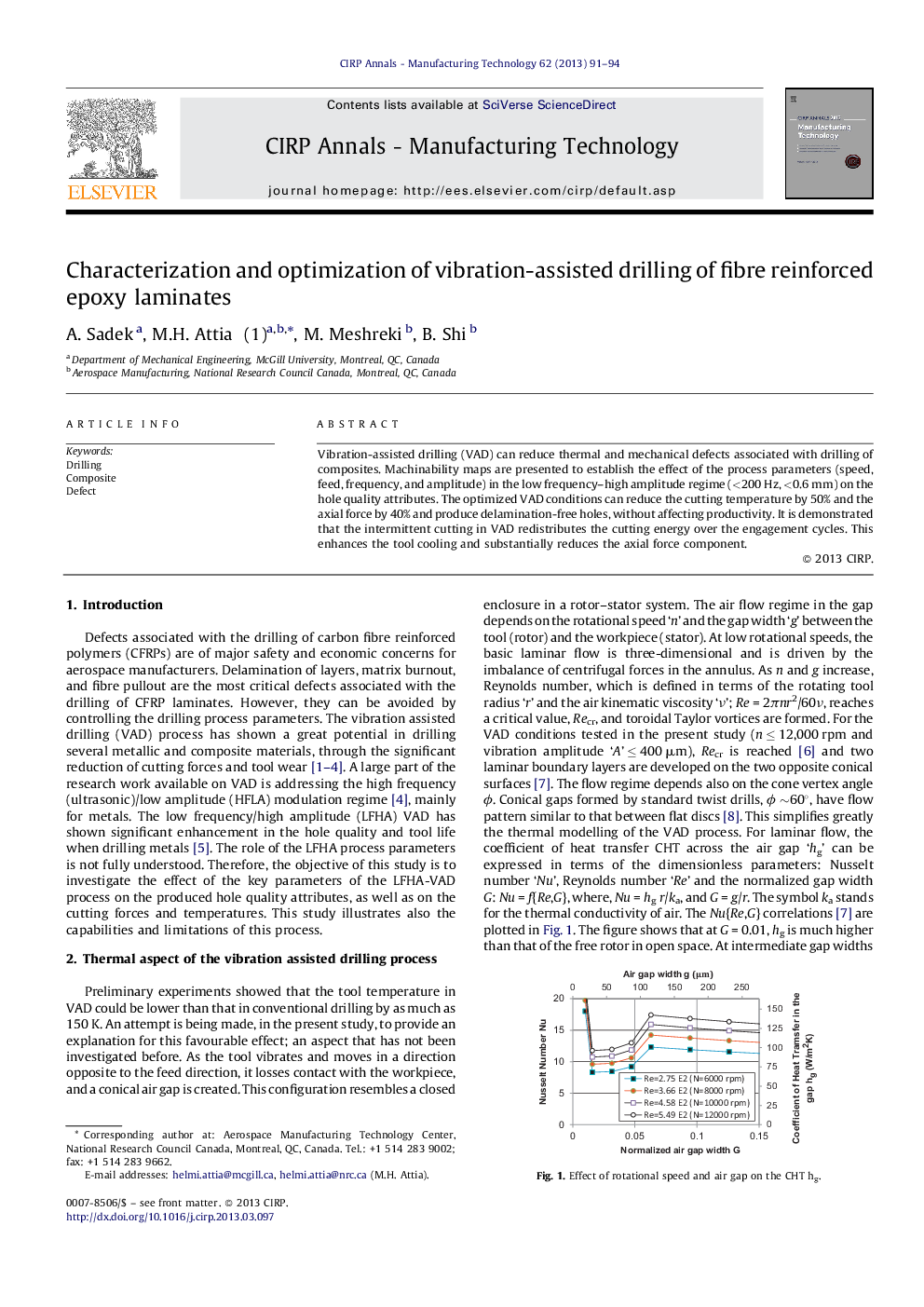

Vibration-assisted drilling (VAD) can reduce thermal and mechanical defects associated with drilling of composites. Machinability maps are presented to establish the effect of the process parameters (speed, feed, frequency, and amplitude) in the low frequency-high amplitude regime (<200Â Hz, <0.6Â mm) on the hole quality attributes. The optimized VAD conditions can reduce the cutting temperature by 50% and the axial force by 40% and produce delamination-free holes, without affecting productivity. It is demonstrated that the intermittent cutting in VAD redistributes the cutting energy over the engagement cycles. This enhances the tool cooling and substantially reduces the axial force component.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

A. Sadek, M.H. Attia, M. Meshreki, B. Shi,