| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674394 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

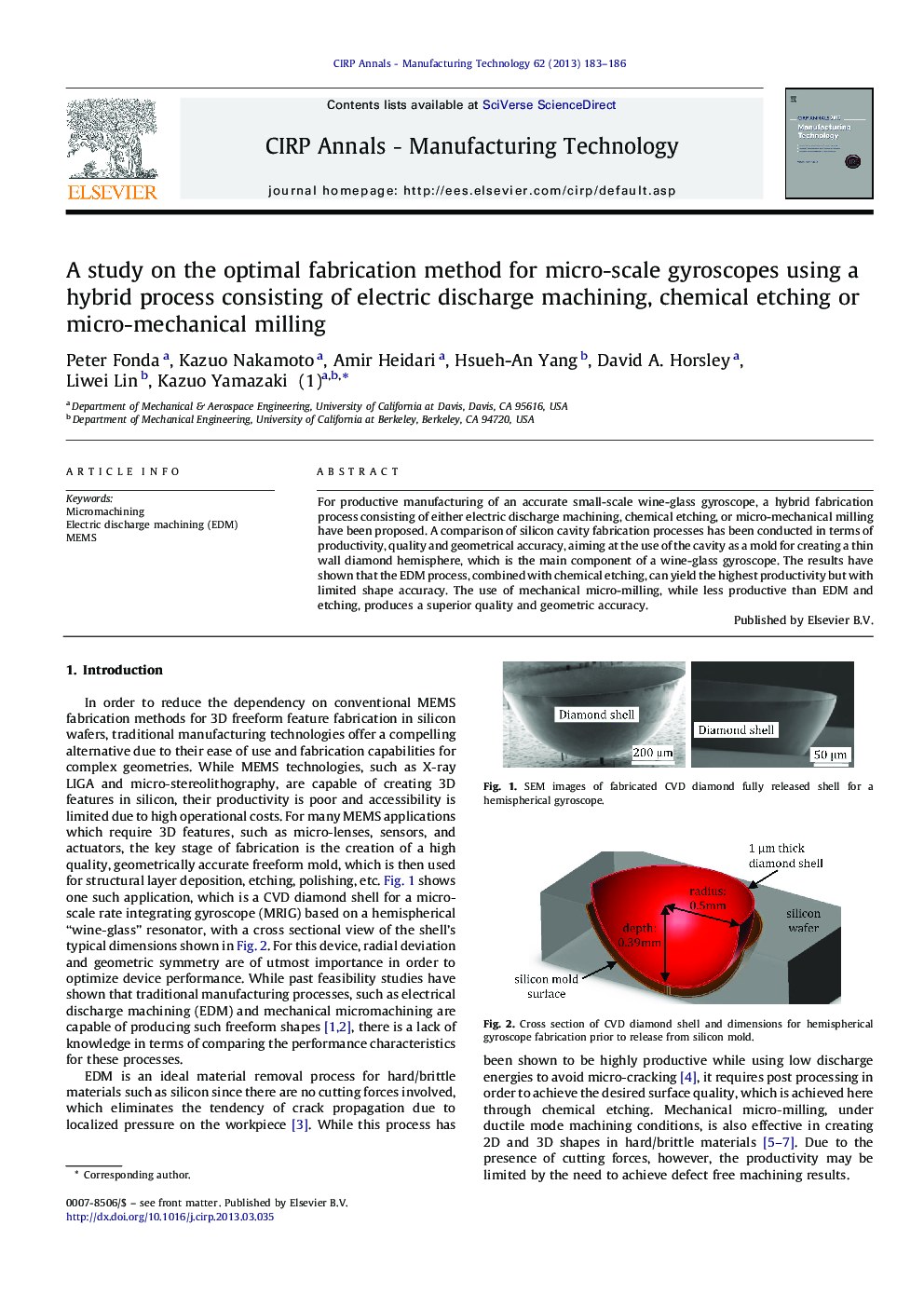

For productive manufacturing of an accurate small-scale wine-glass gyroscope, a hybrid fabrication process consisting of either electric discharge machining, chemical etching, or micro-mechanical milling have been proposed. A comparison of silicon cavity fabrication processes has been conducted in terms of productivity, quality and geometrical accuracy, aiming at the use of the cavity as a mold for creating a thin wall diamond hemisphere, which is the main component of a wine-glass gyroscope. The results have shown that the EDM process, combined with chemical etching, can yield the highest productivity but with limited shape accuracy. The use of mechanical micro-milling, while less productive than EDM and etching, produces a superior quality and geometric accuracy.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Peter Fonda, Kazuo Nakamoto, Amir Heidari, Hsueh-An Yang, David A. Horsley, Liwei Lin, Kazuo Yamazaki,