| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674433 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

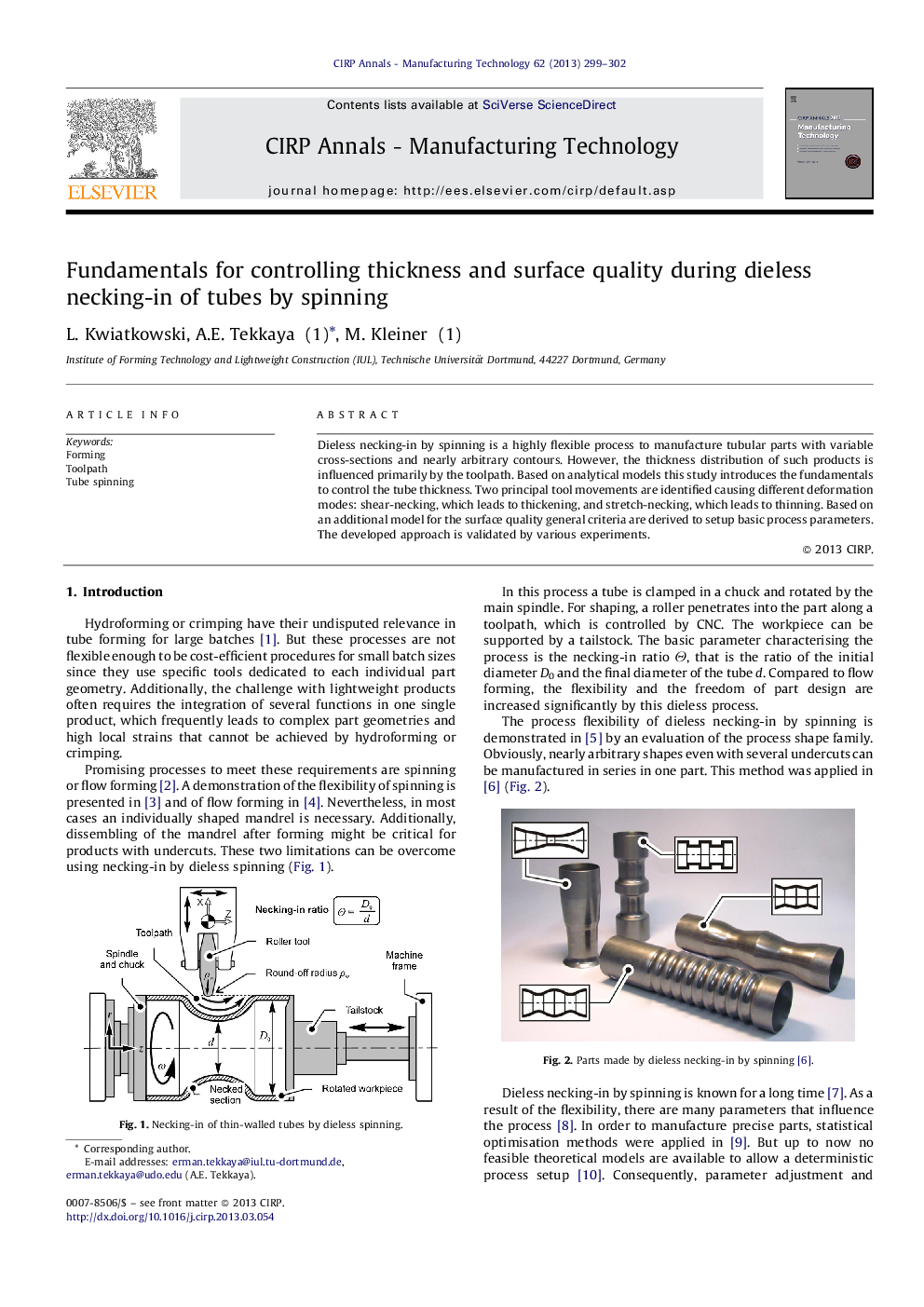

Dieless necking-in by spinning is a highly flexible process to manufacture tubular parts with variable cross-sections and nearly arbitrary contours. However, the thickness distribution of such products is influenced primarily by the toolpath. Based on analytical models this study introduces the fundamentals to control the tube thickness. Two principal tool movements are identified causing different deformation modes: shear-necking, which leads to thickening, and stretch-necking, which leads to thinning. Based on an additional model for the surface quality general criteria are derived to setup basic process parameters. The developed approach is validated by various experiments.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

L. Kwiatkowski, A.E. Tekkaya, M. Kleiner,