| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674439 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

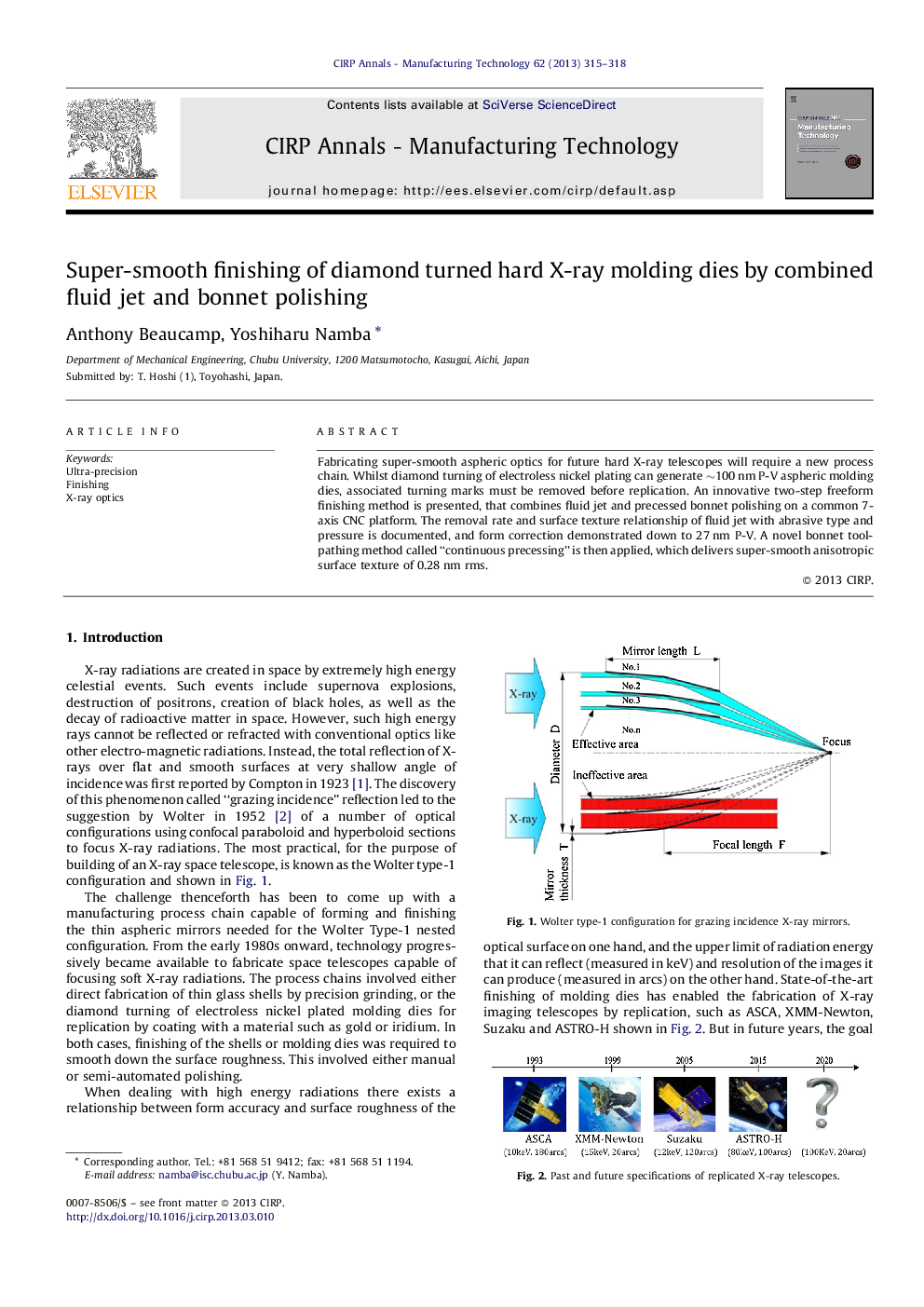

Fabricating super-smooth aspheric optics for future hard X-ray telescopes will require a new process chain. Whilst diamond turning of electroless nickel plating can generate ~100Â nm P-V aspheric molding dies, associated turning marks must be removed before replication. An innovative two-step freeform finishing method is presented, that combines fluid jet and precessed bonnet polishing on a common 7-axis CNC platform. The removal rate and surface texture relationship of fluid jet with abrasive type and pressure is documented, and form correction demonstrated down to 27Â nm P-V. A novel bonnet tool-pathing method called “continuous precessing” is then applied, which delivers super-smooth anisotropic surface texture of 0.28Â nm rms.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Anthony Beaucamp, Yoshiharu Namba,