| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674447 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

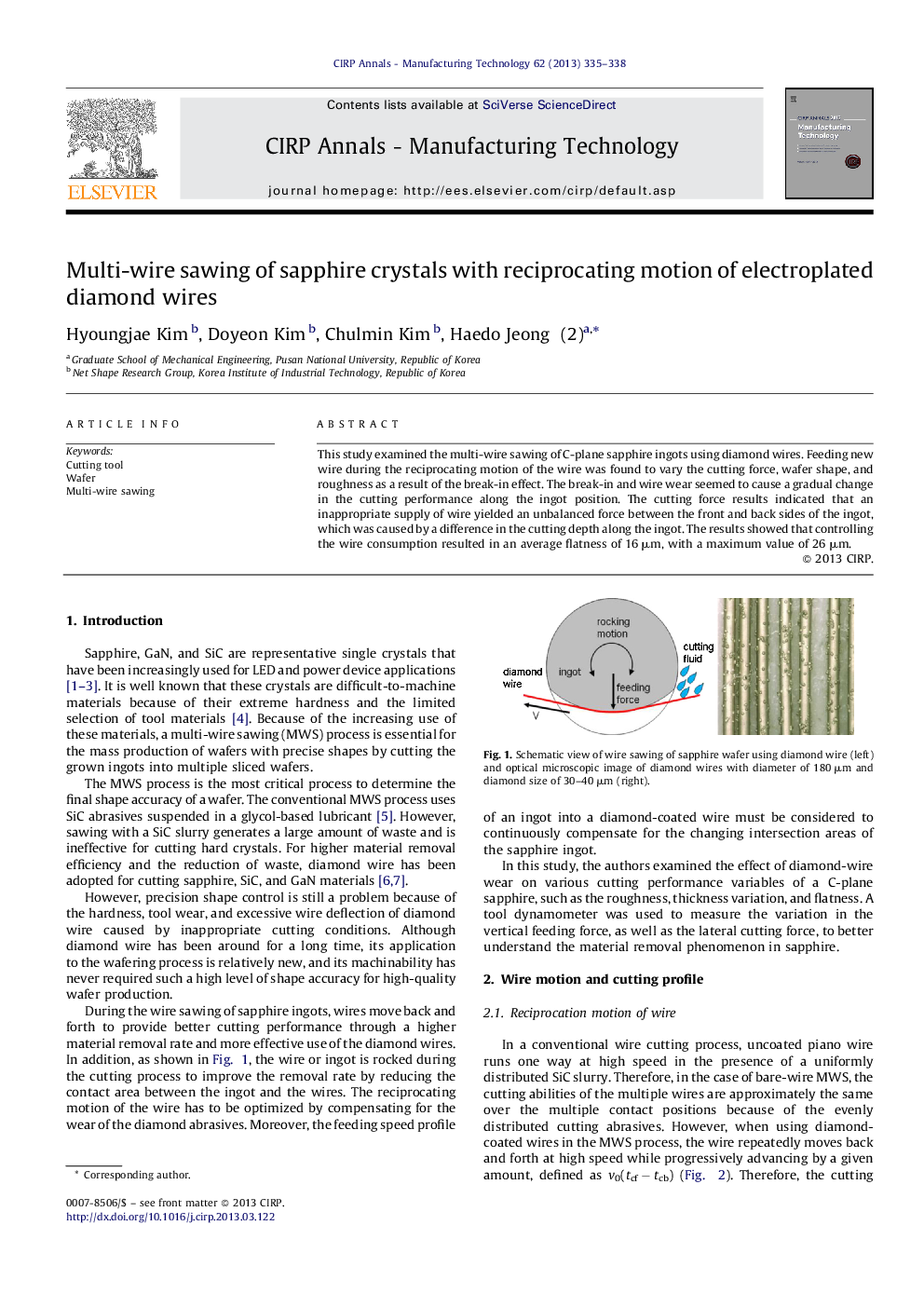

This study examined the multi-wire sawing of C-plane sapphire ingots using diamond wires. Feeding new wire during the reciprocating motion of the wire was found to vary the cutting force, wafer shape, and roughness as a result of the break-in effect. The break-in and wire wear seemed to cause a gradual change in the cutting performance along the ingot position. The cutting force results indicated that an inappropriate supply of wire yielded an unbalanced force between the front and back sides of the ingot, which was caused by a difference in the cutting depth along the ingot. The results showed that controlling the wire consumption resulted in an average flatness of 16 μm, with a maximum value of 26 μm.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Hyoungjae Kim, Doyeon Kim, Chulmin Kim, Haedo Jeong,