| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674451 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

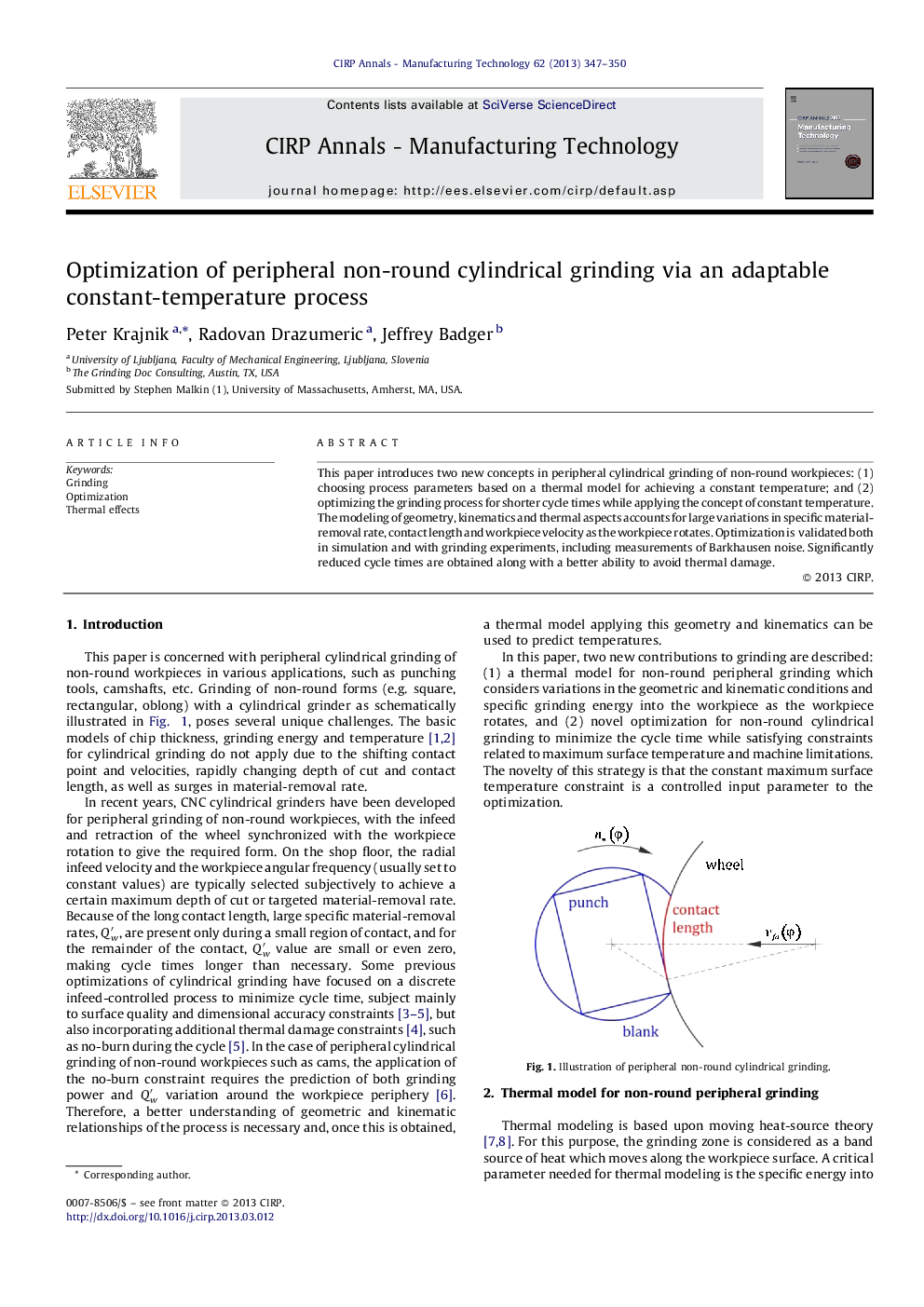

This paper introduces two new concepts in peripheral cylindrical grinding of non-round workpieces: (1) choosing process parameters based on a thermal model for achieving a constant temperature; and (2) optimizing the grinding process for shorter cycle times while applying the concept of constant temperature. The modeling of geometry, kinematics and thermal aspects accounts for large variations in specific material-removal rate, contact length and workpiece velocity as the workpiece rotates. Optimization is validated both in simulation and with grinding experiments, including measurements of Barkhausen noise. Significantly reduced cycle times are obtained along with a better ability to avoid thermal damage.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Peter Krajnik, Radovan Drazumeric, Jeffrey Badger,