| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674453 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

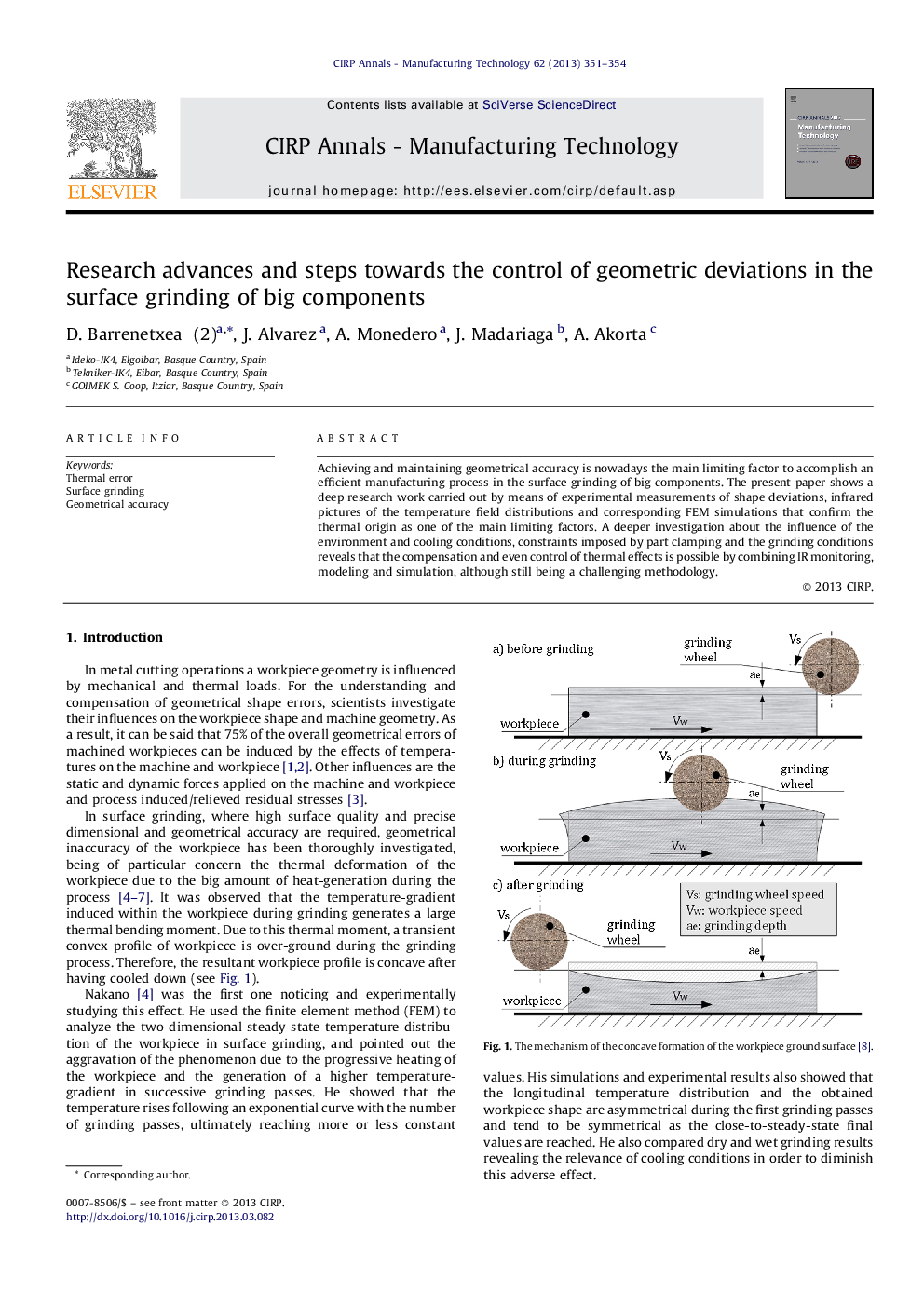

Achieving and maintaining geometrical accuracy is nowadays the main limiting factor to accomplish an efficient manufacturing process in the surface grinding of big components. The present paper shows a deep research work carried out by means of experimental measurements of shape deviations, infrared pictures of the temperature field distributions and corresponding FEM simulations that confirm the thermal origin as one of the main limiting factors. A deeper investigation about the influence of the environment and cooling conditions, constraints imposed by part clamping and the grinding conditions reveals that the compensation and even control of thermal effects is possible by combining IR monitoring, modeling and simulation, although still being a challenging methodology.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

D. Barrenetxea, J. Alvarez, A. Monedero, J. Madariaga, A. Akorta,