| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674469 | CIRP Annals - Manufacturing Technology | 2013 | 4 Pages |

Abstract

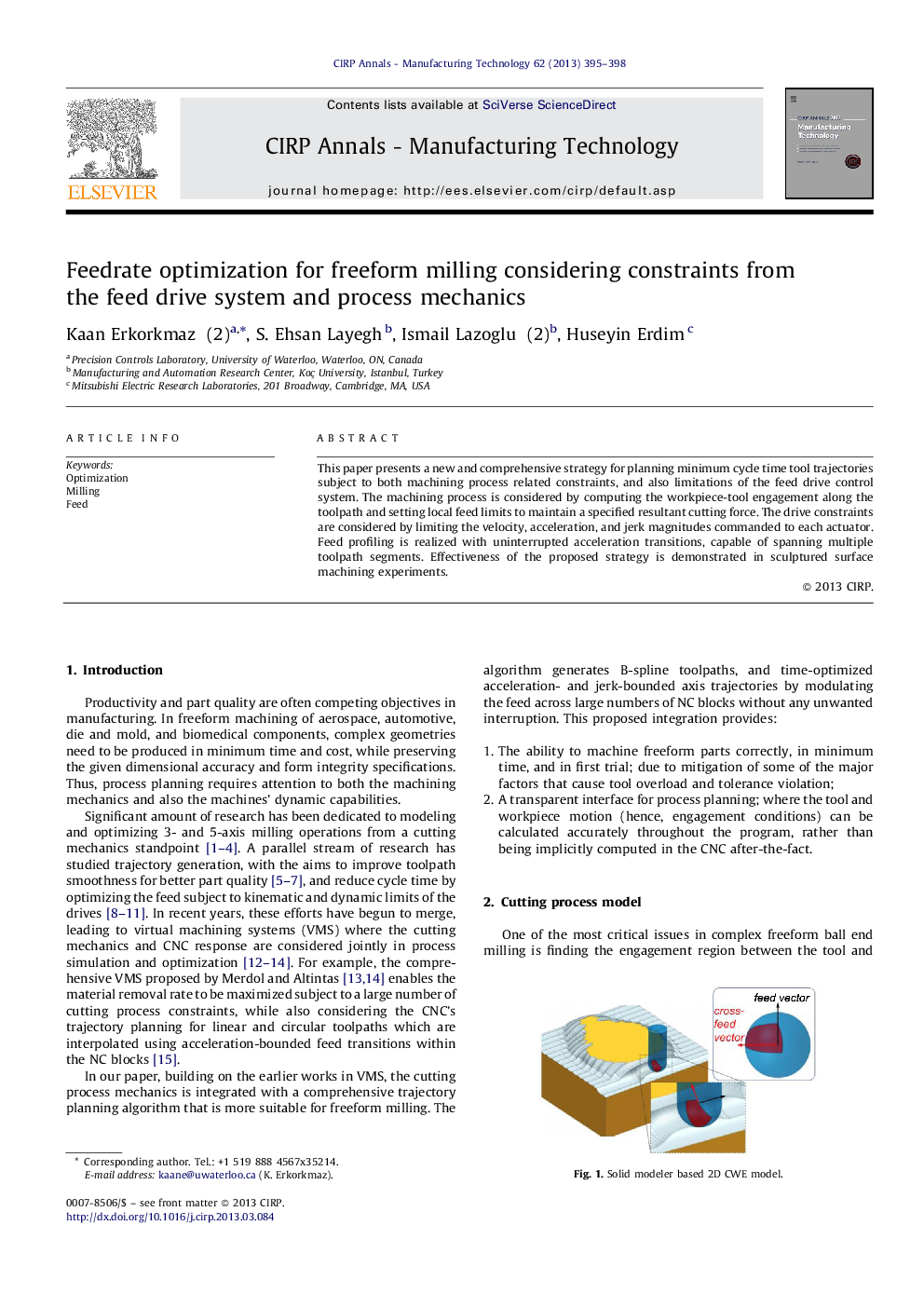

This paper presents a new and comprehensive strategy for planning minimum cycle time tool trajectories subject to both machining process related constraints, and also limitations of the feed drive control system. The machining process is considered by computing the workpiece-tool engagement along the toolpath and setting local feed limits to maintain a specified resultant cutting force. The drive constraints are considered by limiting the velocity, acceleration, and jerk magnitudes commanded to each actuator. Feed profiling is realized with uninterrupted acceleration transitions, capable of spanning multiple toolpath segments. Effectiveness of the proposed strategy is demonstrated in sculptured surface machining experiments.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Kaan Erkorkmaz, S. Ehsan Layegh, Ismail Lazoglu, Huseyin Erdim,