| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674604 | CIRP Annals - Manufacturing Technology | 2007 | 4 Pages |

Abstract

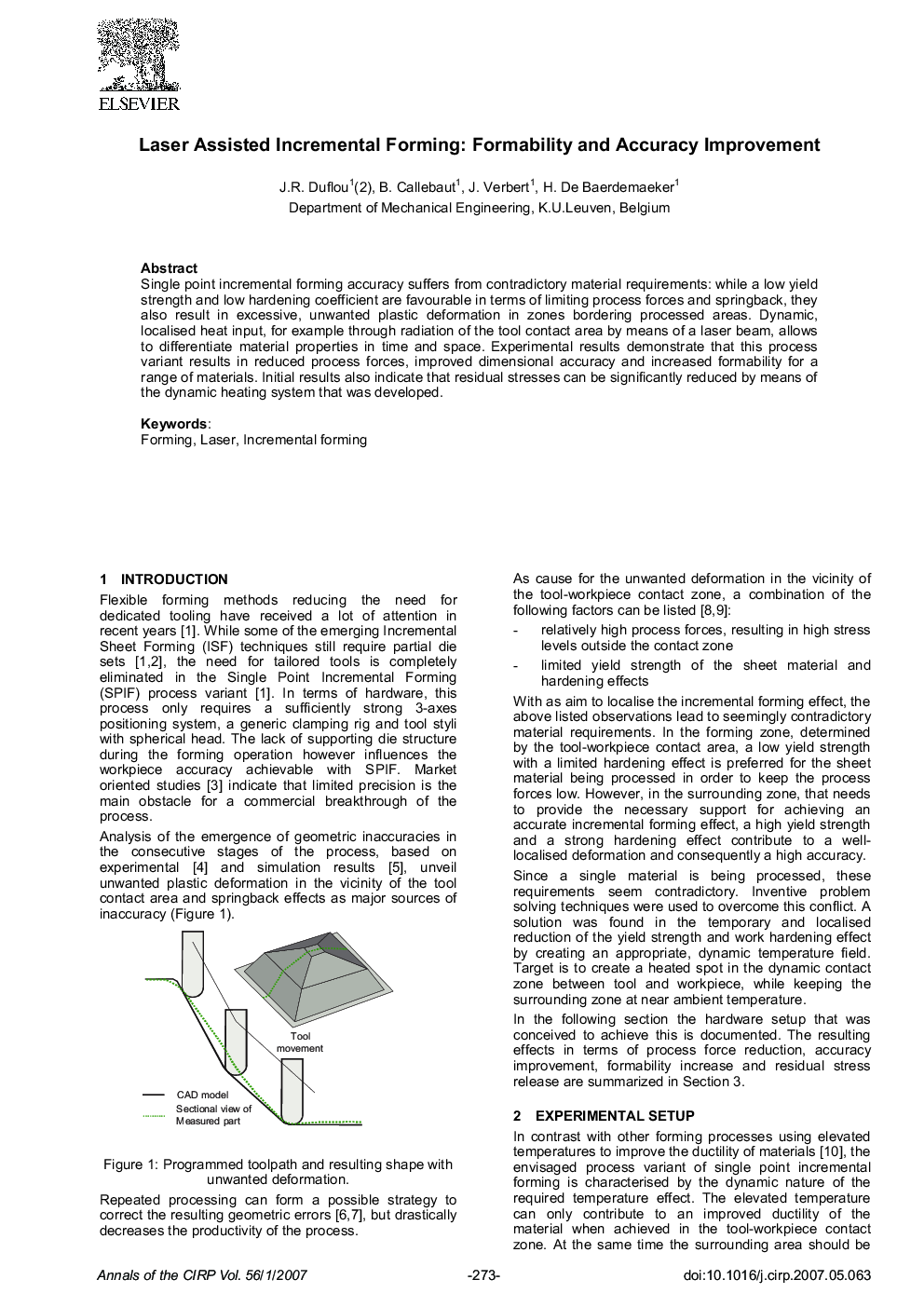

Single point incremental forming accuracy suffers from contradictory material requirements: while a low yield strength and low hardening coefficient are favourable in terms of limiting process forces and springback, they also result in excessive, unwanted plastic deformation in zones bordering processed areas. Dynamic, localised heat input, for example through radiation of the tool contact area by means of a laser beam, allows to differentiate material properties in time and space. Experimental results demonstrate that this process variant results in reduced process forces, improved dimensional accuracy and increased formability for a range of materials. Initial results also indicate that residual stresses can be significantly reduced by means of the dynamic heating system that was developed.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

J.R. Duflou, B. Callebaut, J. Verbert, H. De Baerdemaeker,