| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674615 | CIRP Annals - Manufacturing Technology | 2007 | 4 Pages |

Abstract

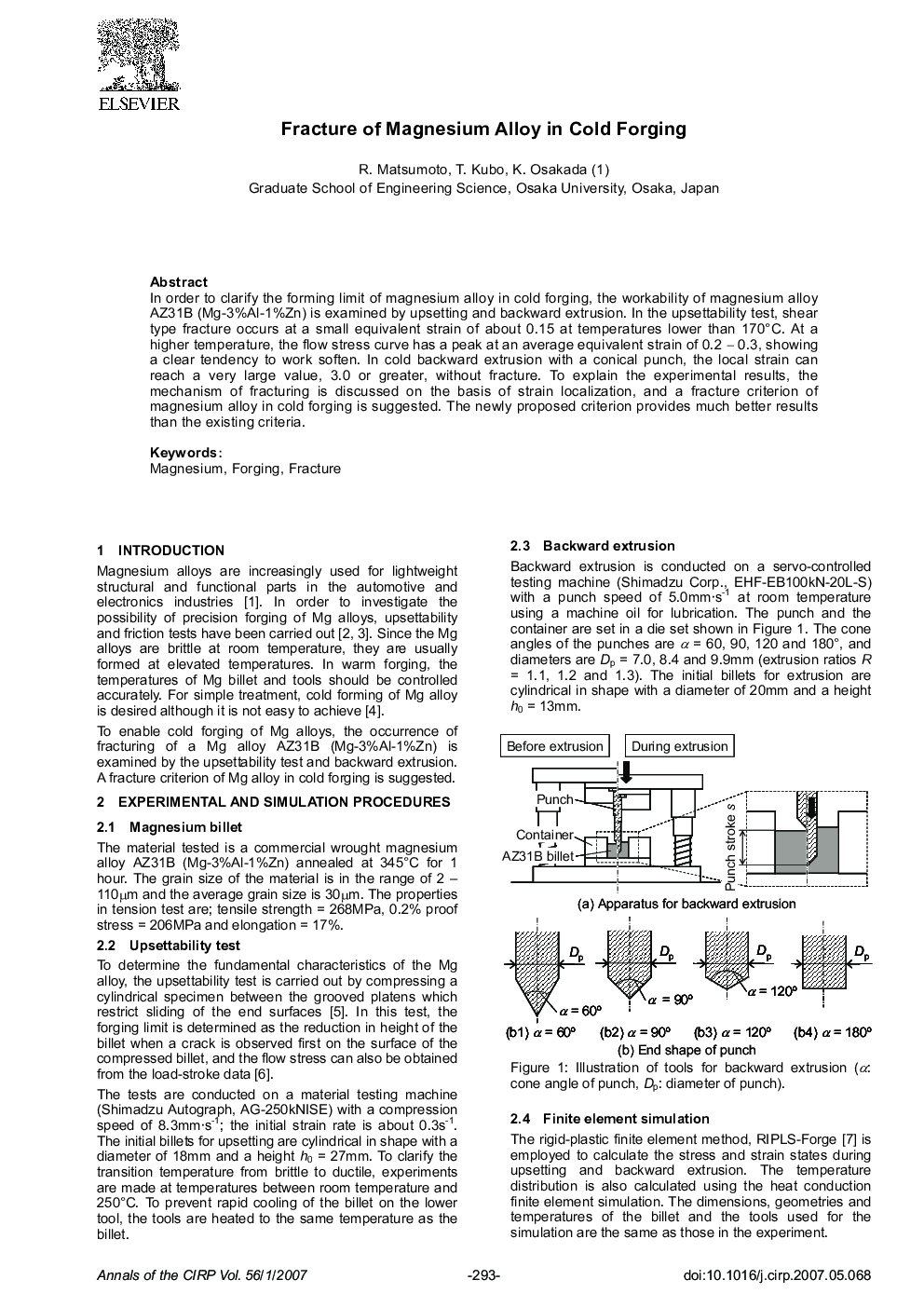

In order to clarify the forming limit of magnesium alloy in cold forging, the workability of magnesium alloy AZ31B (Mg-3%Al-1%Zn) is examined by upsetting and backward extrusion. In the upsettability test, shear type fracture occurs at a small equivalent strain of about 0.15 at temperatures lower than 170 °C. At a higher temperature, the flow stress curve has a peak at an average equivalent strain of 0.2-0.3, showing a clear tendency to work soften. In cold backward extrusion with a conical punch, the local strain can reach a very large value, 3.0 or greater, without fracture. To explain the experimental results, the mechanism of fracturing is discussed on the basis of strain localization, and a fracture criterion of magnesium alloy in cold forging is suggested. The newly proposed criterion provides much better results than the existing criteria.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

R. Matsumoto, T. Kubo, K. Osakada,