| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674620 | CIRP Annals - Manufacturing Technology | 2007 | 6 Pages |

Abstract

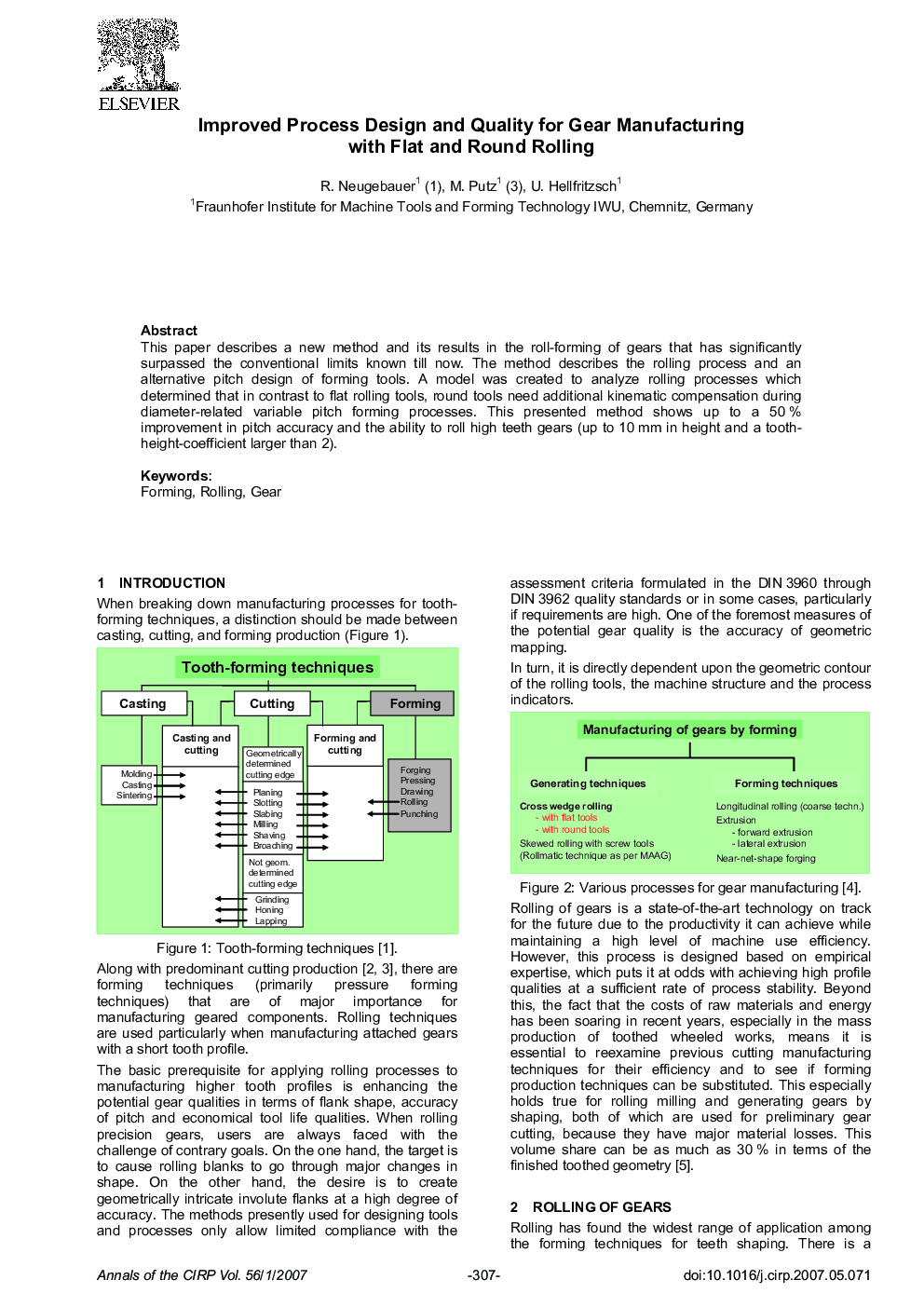

This paper describes a new method and its results in the roll-forming of gears that has significantly surpassed the conventional limits known till now. The method describes the rolling process and an alternative pitch design of forming tools. A model was created to analyze rolling processes which determined that in contrast to flat rolling tools, round tools need additional kinematic compensation during diameter-related variable pitch forming processes. This presented method shows up to a 50% improvement in pitch accuracy and the ability to roll high teeth gears (up to 10Â mm in height and a tooth-height-coefficient larger than 2).

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

R. Neugebauer, M. Putz, U. Hellfritzsch,