| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 10674628 | CIRP Annals - Manufacturing Technology | 2007 | 4 Pages |

Abstract

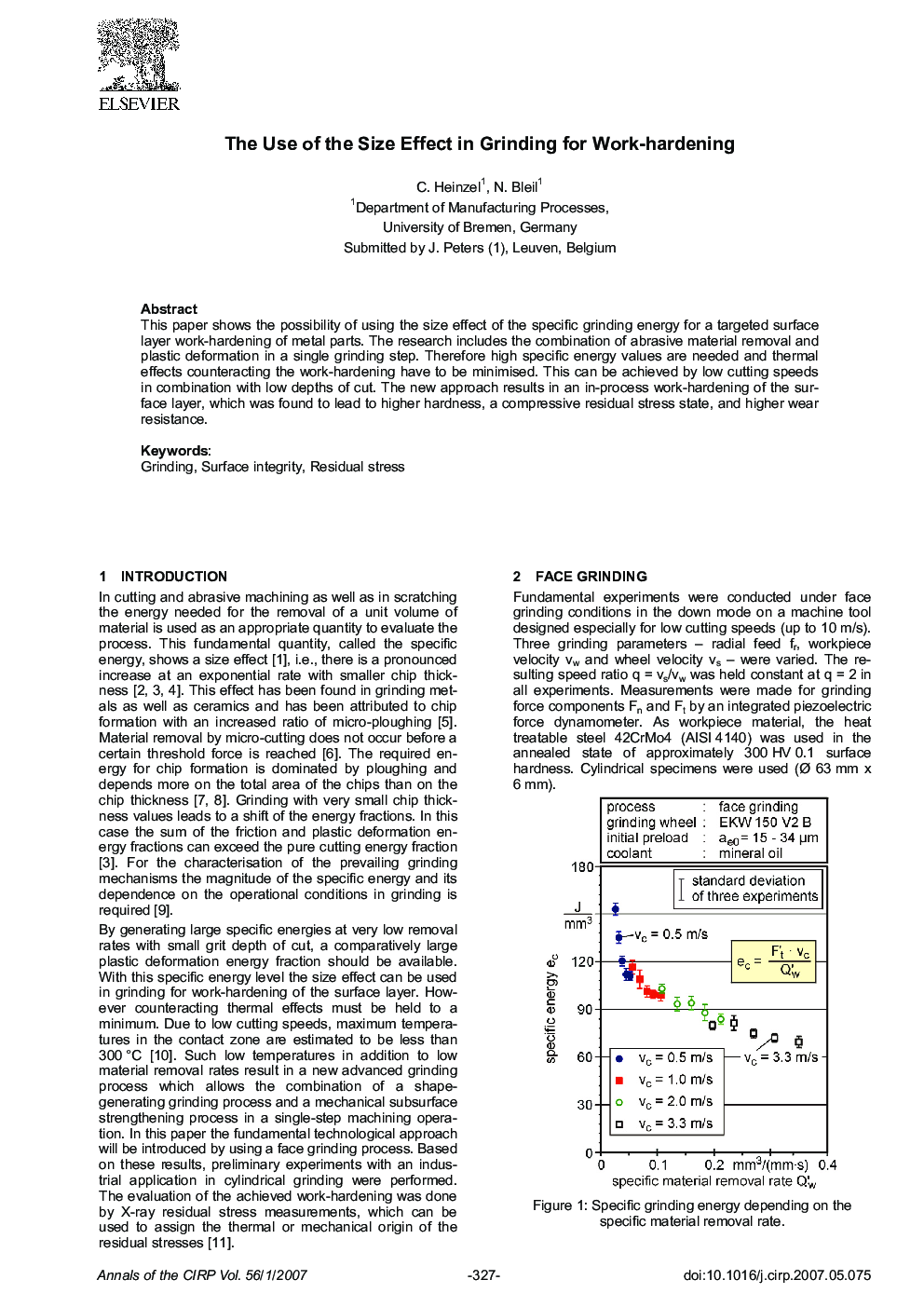

This paper shows the possibility of using the size effect of the specific grinding energy for a targeted surface layer work-hardening of metal parts. The research includes the combination of abrasive material removal and plastic deformation in a single grinding step. Therefore high specific energy values are needed and thermal effects counteracting the work-hardening have to be minimised. This can be achieved by low cutting speeds in combination with low depths of cut. The new approach results in an in-process work-hardening of the surface layer, which was found to lead to higher hardness, a compressive residual stress state, and higher wear resistance.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

C. Heinzel, N. Bleil,