| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1260855 | Journal of Rare Earths | 2006 | 5 Pages |

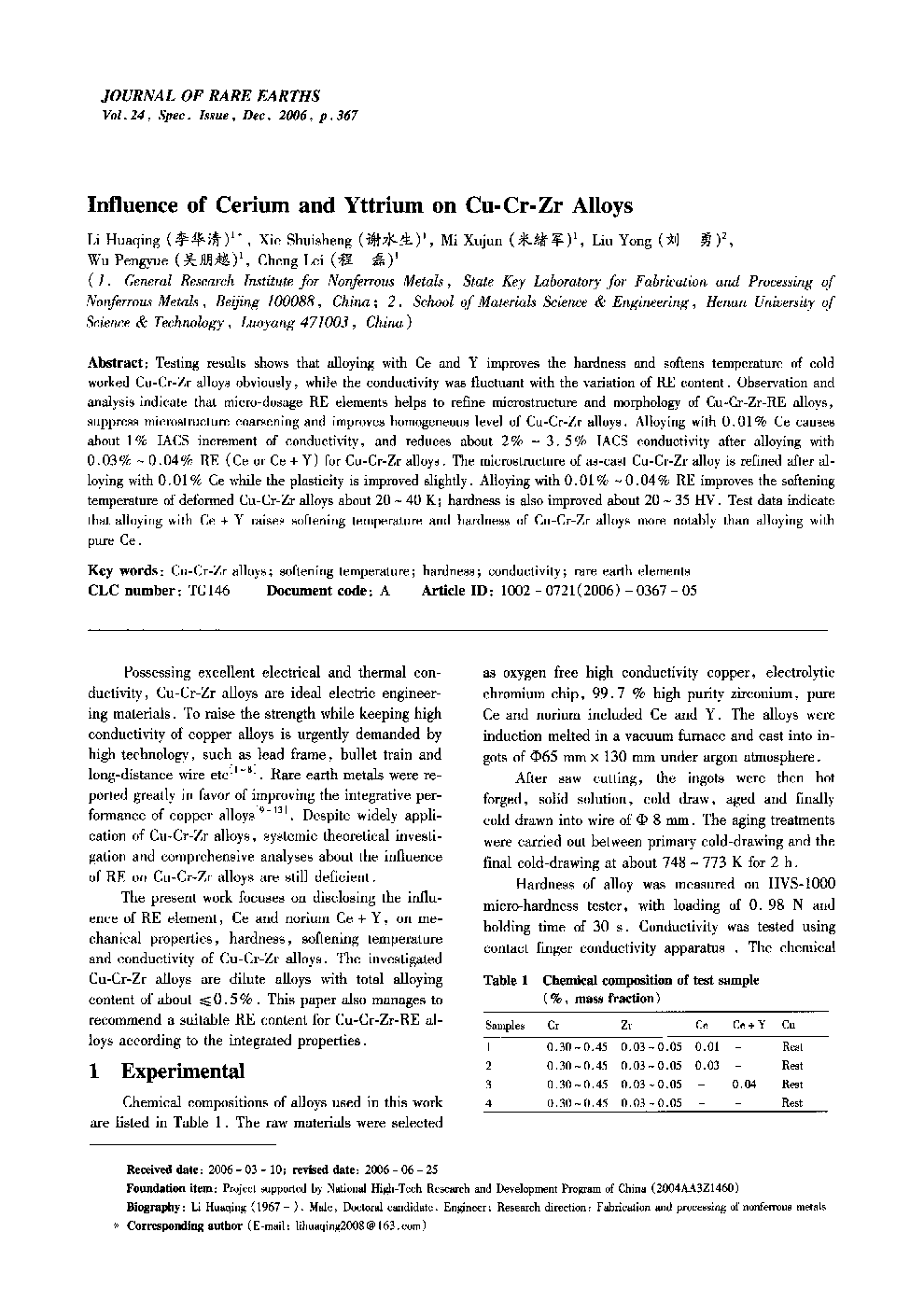

Testing results shows that alloying with Ce and Y improves the hardness and softens temperature of cold worked Cu-Cr-Zr alloys obviously, while the conductivity was fluctuant with the variation of RE content. Observation and analysis indicate that micro-dosage RE elements helps to refine microstructure and morphology of Cu-Cr-Zr-RE alloys, suppress microstructure coarsening and improves homogeneous level of Cu-Cr-Zr alloys. Alloying with 0.01% Ce causes about 1% IACS increment of conductivity, and reduces about 2 % ∼ 3.5% IACS conductivity after alloying with 0.03 % ∼ 0.04 % RE (Ce or Ce + Y) for Cu-Cr-Zr alloys. The microstructure of as-cast Cu-Cr-Zr alloy is refined after alloying with 0.01% Ce while the plasticity is improved slightly. Alloying with 0.01% ∼ 0.04% RE improves the softening temperature of deformed Cu-Cr-Zr alloys about 20 ∼ 40 K; hardness is also improved about 20 ∼ 35 HV. Test data indicate that alloying with Ce + Y raises softening temperature and hardness of Cu-Cr-Zr alloys more notably than alloying with pure Ce.