| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1520397 | Materials Chemistry and Physics | 2016 | 9 Pages |

•A non-hazardous graphitic ink for thermal DOD inkjet printing was developed.•The ternary mixture water/ethylene glycol/2-propanol is suitable as solvent.•Physical properties important for jetting is tailored by solvent composition.•Surfactant-aided grinding gives exfoliation of graphite without inflicting microstrain.

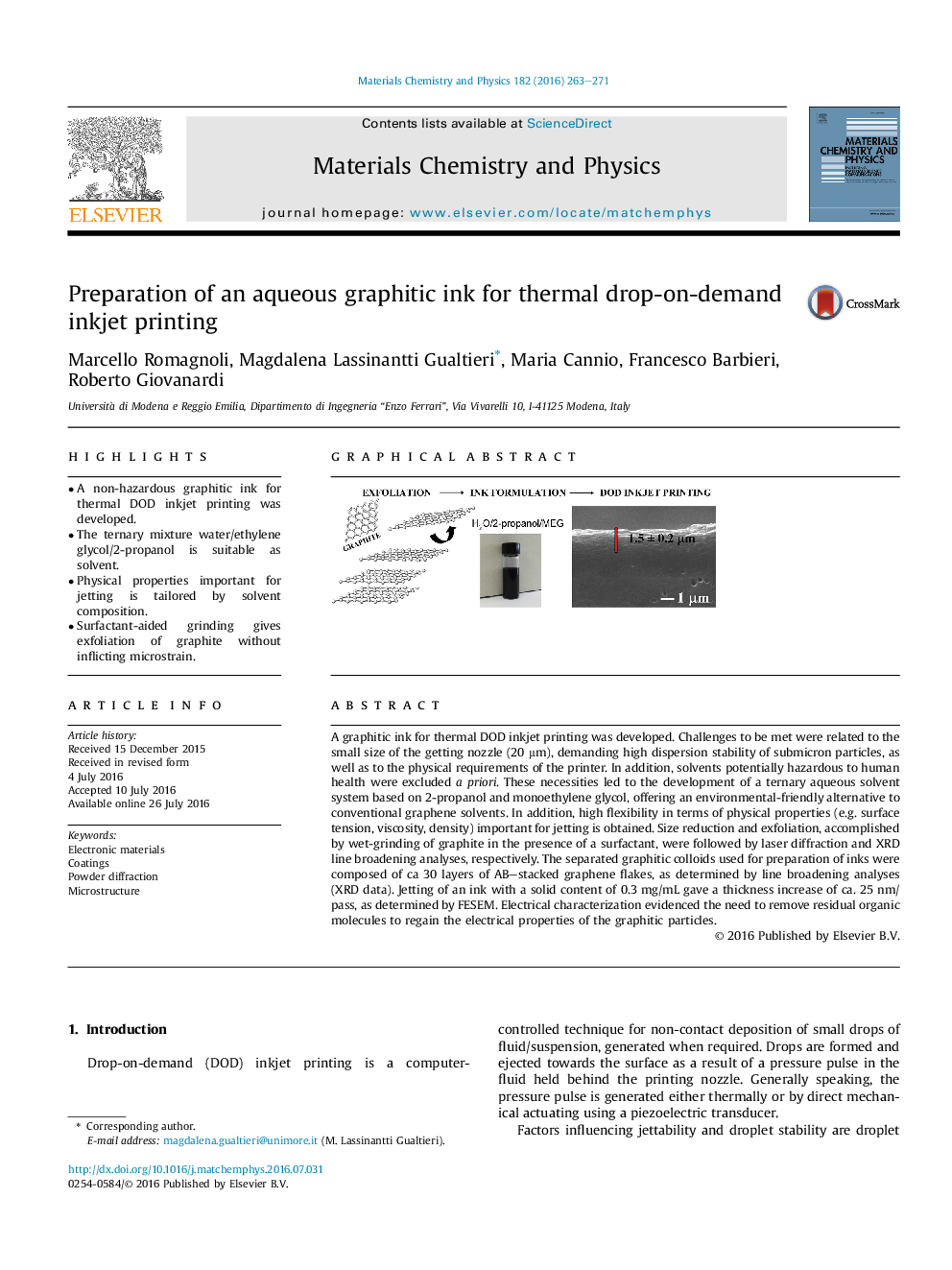

A graphitic ink for thermal DOD inkjet printing was developed. Challenges to be met were related to the small size of the getting nozzle (20 μm), demanding high dispersion stability of submicron particles, as well as to the physical requirements of the printer. In addition, solvents potentially hazardous to human health were excluded a priori. These necessities led to the development of a ternary aqueous solvent system based on 2-propanol and monoethylene glycol, offering an environmental-friendly alternative to conventional graphene solvents. In addition, high flexibility in terms of physical properties (e.g. surface tension, viscosity, density) important for jetting is obtained. Size reduction and exfoliation, accomplished by wet-grinding of graphite in the presence of a surfactant, were followed by laser diffraction and XRD line broadening analyses, respectively. The separated graphitic colloids used for preparation of inks were composed of ca 30 layers of AB–stacked graphene flakes, as determined by line broadening analyses (XRD data). Jetting of an ink with a solid content of 0.3 mg/mL gave a thickness increase of ca. 25 nm/pass, as determined by FESEM. Electrical characterization evidenced the need to remove residual organic molecules to regain the electrical properties of the graphitic particles.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide