| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1520822 | Materials Chemistry and Physics | 2016 | 6 Pages |

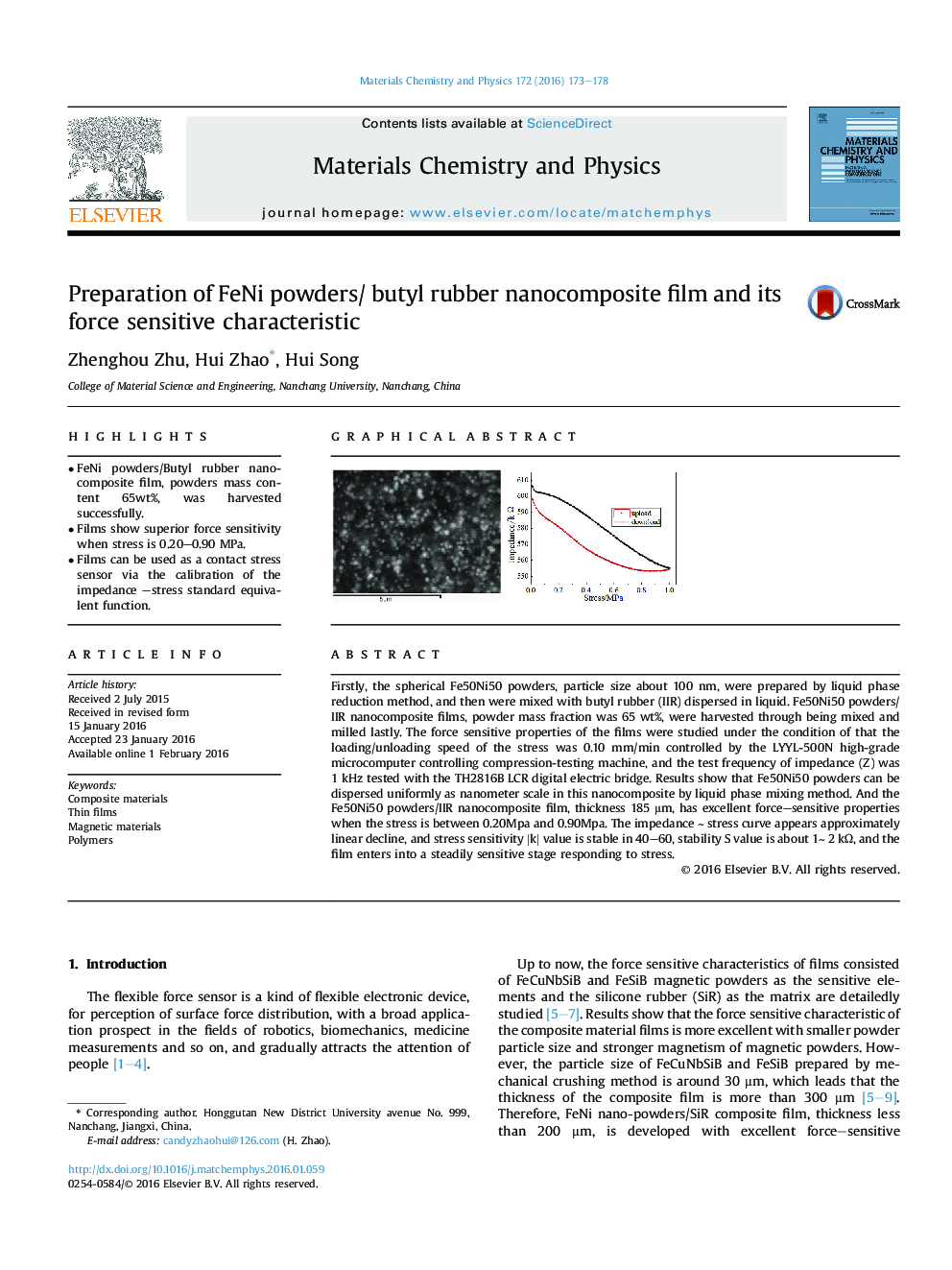

•FeNi powders/Butyl rubber nano-composite film, powders mass content 65wt%, was harvested successfully.•Films show superior force sensitivity when stress is 0.20–0.90 MPa.•Films can be used as a contact stress sensor via the calibration of the impedance –stress standard equivalent function.

Firstly, the spherical Fe50Ni50 powders, particle size about 100 nm, were prepared by liquid phase reduction method, and then were mixed with butyl rubber (IIR) dispersed in liquid. Fe50Ni50 powders/IIR nanocomposite films, powder mass fraction was 65 wt%, were harvested through being mixed and milled lastly. The force sensitive properties of the films were studied under the condition of that the loading/unloading speed of the stress was 0.10 mm/min controlled by the LYYL-500N high-grade microcomputer controlling compression-testing machine, and the test frequency of impedance (Z) was 1 kHz tested with the TH2816B LCR digital electric bridge. Results show that Fe50Ni50 powders can be dispersed uniformly as nanometer scale in this nanocomposite by liquid phase mixing method. And the Fe50Ni50 powders/IIR nanocomposite film, thickness 185 μm, has excellent force–sensitive properties when the stress is between 0.20Mpa and 0.90Mpa. The impedance ∼ stress curve appears approximately linear decline, and stress sensitivity |k| value is stable in 40–60, stability S value is about 1∼ 2 kΩ, and the film enters into a steadily sensitive stage responding to stress.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide