| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1521308 | Materials Chemistry and Physics | 2015 | 8 Pages |

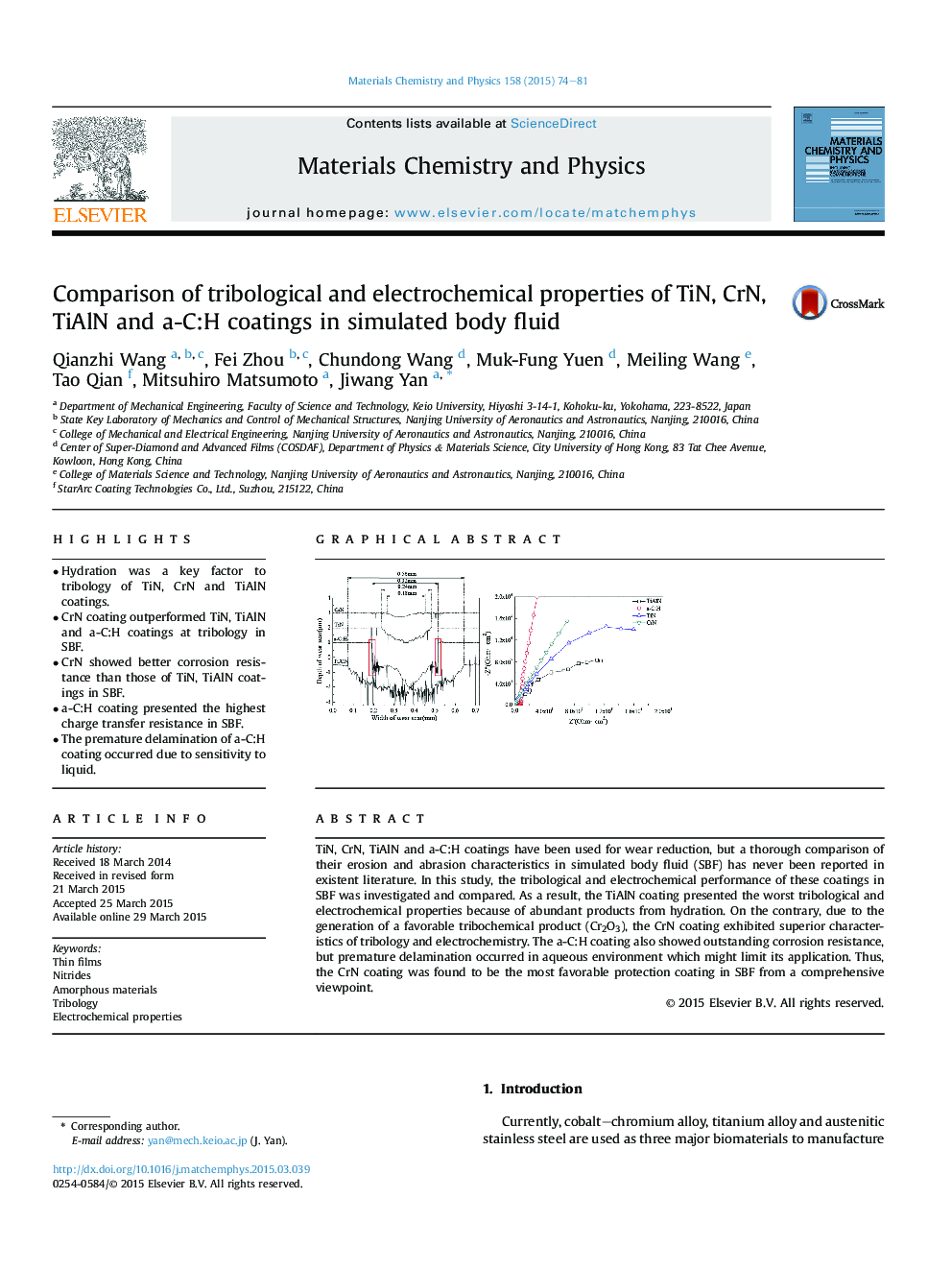

•Hydration was a key factor to tribology of TiN, CrN and TiAlN coatings.•CrN coating outperformed TiN, TiAlN and a-C:H coatings at tribology in SBF.•CrN showed better corrosion resistance than those of TiN, TiAlN coatings in SBF.•a-C:H coating presented the highest charge transfer resistance in SBF.•The premature delamination of a-C:H coating occurred due to sensitivity to liquid.

TiN, CrN, TiAlN and a-C:H coatings have been used for wear reduction, but a thorough comparison of their erosion and abrasion characteristics in simulated body fluid (SBF) has never been reported in existent literature. In this study, the tribological and electrochemical performance of these coatings in SBF was investigated and compared. As a result, the TiAlN coating presented the worst tribological and electrochemical properties because of abundant products from hydration. On the contrary, due to the generation of a favorable tribochemical product (Cr2O3), the CrN coating exhibited superior characteristics of tribology and electrochemistry. The a-C:H coating also showed outstanding corrosion resistance, but premature delamination occurred in aqueous environment which might limit its application. Thus, the CrN coating was found to be the most favorable protection coating in SBF from a comprehensive viewpoint.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide