| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1523812 | Materials Chemistry and Physics | 2012 | 7 Pages |

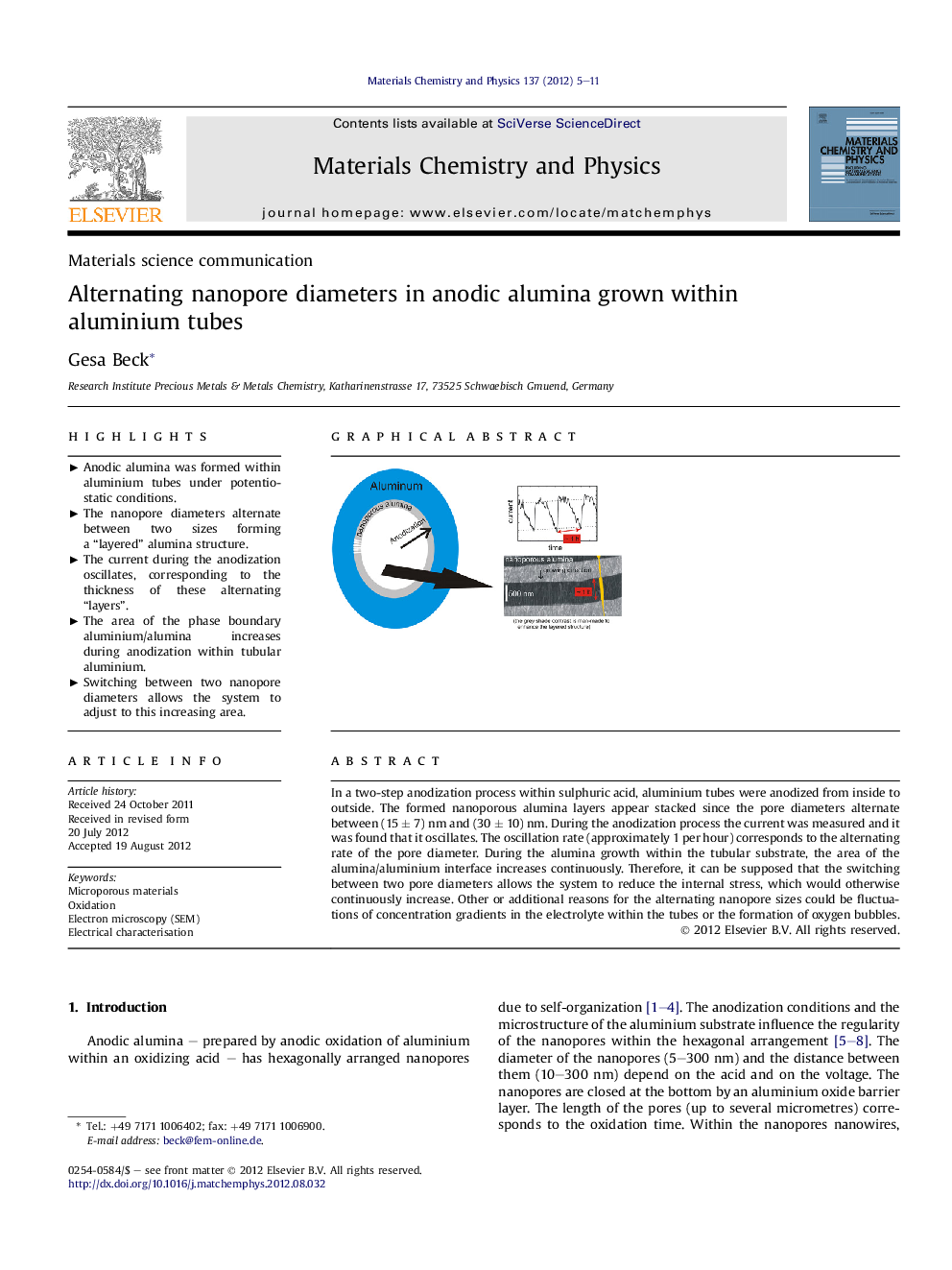

In a two-step anodization process within sulphuric acid, aluminium tubes were anodized from inside to outside. The formed nanoporous alumina layers appear stacked since the pore diameters alternate between (15 ± 7) nm and (30 ± 10) nm. During the anodization process the current was measured and it was found that it oscillates. The oscillation rate (approximately 1 per hour) corresponds to the alternating rate of the pore diameter. During the alumina growth within the tubular substrate, the area of the alumina/aluminium interface increases continuously. Therefore, it can be supposed that the switching between two pore diameters allows the system to reduce the internal stress, which would otherwise continuously increase. Other or additional reasons for the alternating nanopore sizes could be fluctuations of concentration gradients in the electrolyte within the tubes or the formation of oxygen bubbles.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slideHighlights► Anodic alumina was formed within aluminium tubes under potentiostatic conditions. ► The nanopore diameters alternate between two sizes forming a “layered” alumina structure. ► The current during the anodization oscillates, corresponding to the thickness of these alternating “layers”. ► The area of the phase boundary aluminium/alumina increases during anodization within tubular aluminium. ► Switching between two nanopore diameters allows the system to adjust to this increasing area.