| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 154510 | Chemical Engineering Science | 2016 | 9 Pages |

•Catalytic oxidation of ethanol in a monolithic ceramic reactor is modelled.•Significant diffusional resistances at low operating temperatures are found.•Process rate is reduced by internal mass transfer resistances at high VOC conversions.•Poor interfacial areas lead to significant external mass transfer resistances.

A theoretical study of a monolithic reactor for the catalytic oxidation of Volatile Organic Compounds (VOC) over manganese–copper mixed oxide catalysts is presented. An isothermal one-dimensional heterogeneous model is selected to account for the external (gas–solid) and internal (washcoat) mass transport limitations.The results reveal that under certain operating conditions, e.g. thick washcoats and high conversions of VOCs (high temperatures), the overall process rate is reduced by internal diffusion inside the catalyst. At high temperatures and/or monoliths with poor interfacial areas, the overall process rate is limited by external mass transfer resistance to the catalyst. Proper quantification of both internal and external mass transfer resistances by means of a heterogeneous model can result in avoiding situations of incomplete VOC abatement under conditions of high VOC dilution.

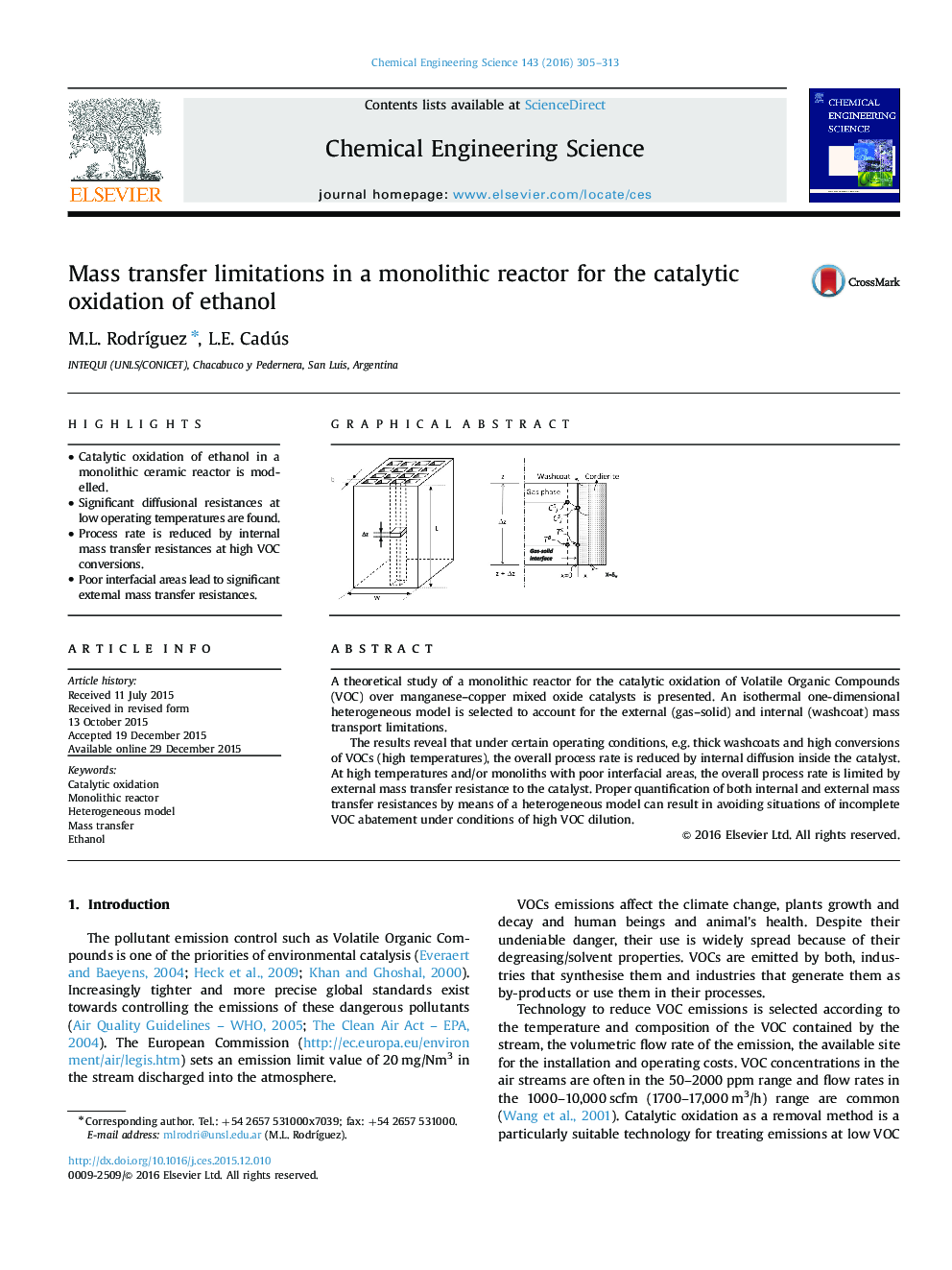

Graphical abstractFigure optionsDownload full-size imageDownload high-quality image (171 K)Download as PowerPoint slide