| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 154616 | Chemical Engineering Science | 2015 | 11 Pages |

•Detailed washcoat diffusion model with multi-step chemistry.•We show the effect of axial solid conduction on cumulative cold-start emissions.•Comparison of foam based and honeycomb reactors.•We propose a correlation that captures the essential features of cold-start.

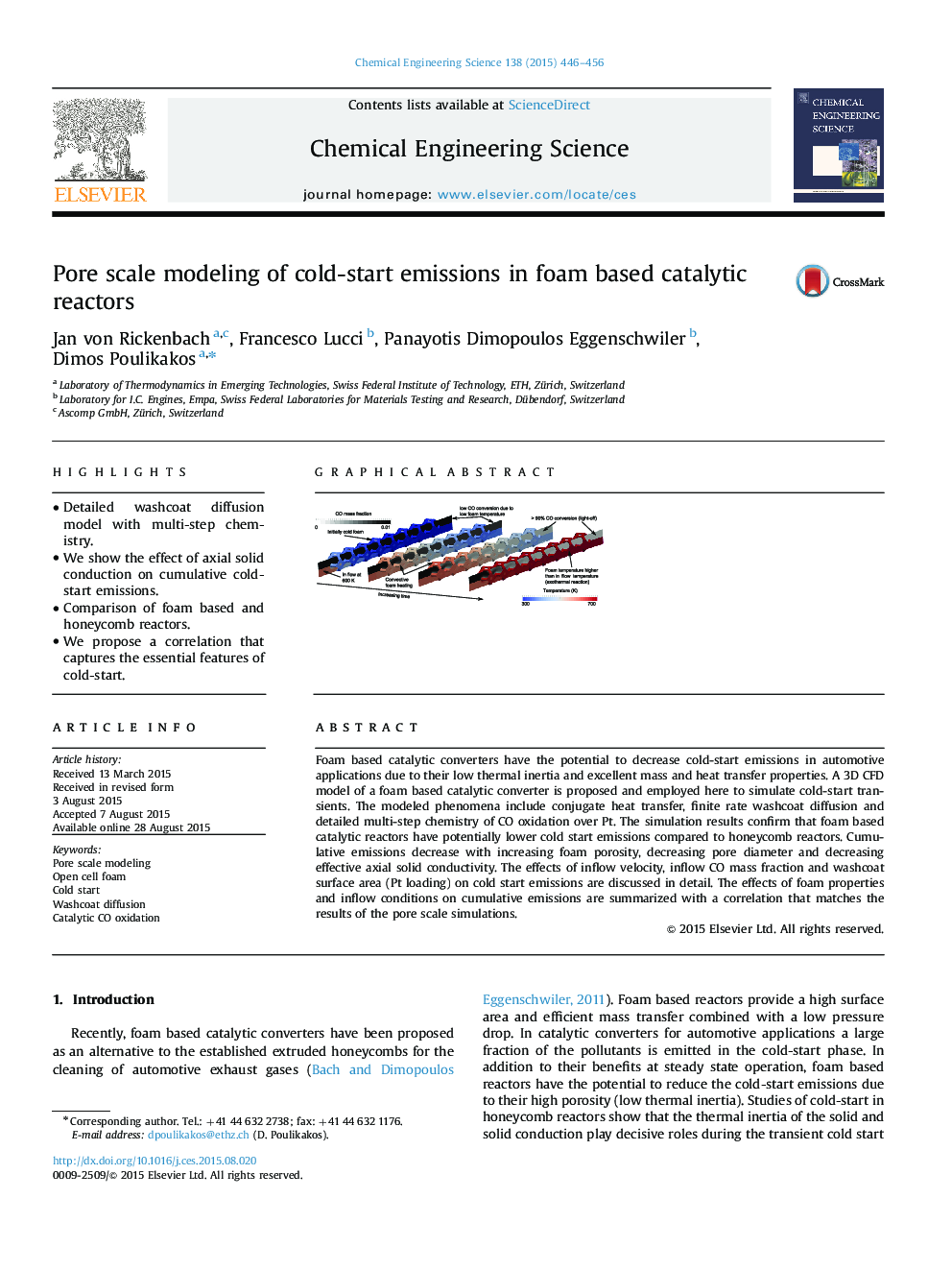

Foam based catalytic converters have the potential to decrease cold-start emissions in automotive applications due to their low thermal inertia and excellent mass and heat transfer properties. A 3D CFD model of a foam based catalytic converter is proposed and employed here to simulate cold-start transients. The modeled phenomena include conjugate heat transfer, finite rate washcoat diffusion and detailed multi-step chemistry of CO oxidation over Pt. The simulation results confirm that foam based catalytic reactors have potentially lower cold start emissions compared to honeycomb reactors. Cumulative emissions decrease with increasing foam porosity, decreasing pore diameter and decreasing effective axial solid conductivity. The effects of inflow velocity, inflow CO mass fraction and washcoat surface area (Pt loading) on cold start emissions are discussed in detail. The effects of foam properties and inflow conditions on cumulative emissions are summarized with a correlation that matches the results of the pore scale simulations.

Graphical abstractFigure optionsDownload full-size imageDownload high-quality image (292 K)Download as PowerPoint slide