| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 154932 | Chemical Engineering Science | 2014 | 11 Pages |

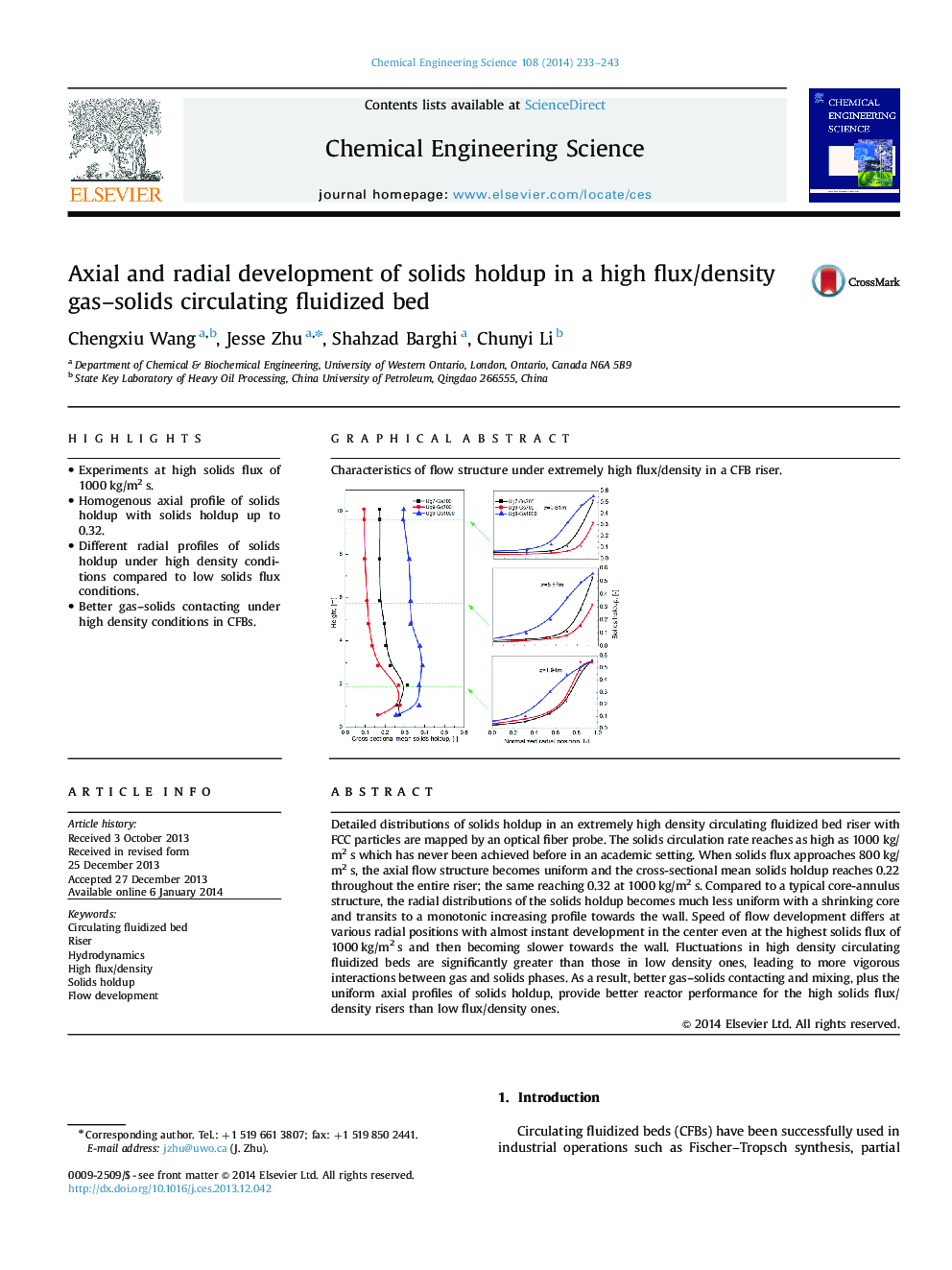

•Experiments at high solids flux of 1000 kg/m2 s.•Homogenous axial profile of solids holdup with solids holdup up to 0.32.•Different radial profiles of solids holdup under high density conditions compared to low solids flux conditions.•Better gas–solids contacting under high density conditions in CFBs.

Detailed distributions of solids holdup in an extremely high density circulating fluidized bed riser with FCC particles are mapped by an optical fiber probe. The solids circulation rate reaches as high as 1000 kg/m2 s which has never been achieved before in an academic setting. When solids flux approaches 800 kg/m2 s, the axial flow structure becomes uniform and the cross-sectional mean solids holdup reaches 0.22 throughout the entire riser; the same reaching 0.32 at 1000 kg/m2 s. Compared to a typical core-annulus structure, the radial distributions of the solids holdup becomes much less uniform with a shrinking core and transits to a monotonic increasing profile towards the wall. Speed of flow development differs at various radial positions with almost instant development in the center even at the highest solids flux of 1000 kg/m2 s and then becoming slower towards the wall. Fluctuations in high density circulating fluidized beds are significantly greater than those in low density ones, leading to more vigorous interactions between gas and solids phases. As a result, better gas–solids contacting and mixing, plus the uniform axial profiles of solids holdup, provide better reactor performance for the high solids flux/density risers than low flux/density ones.

Graphical abstractCharacteristics of flow structure under extremely high flux/density in a CFB riser.Figure optionsDownload full-size imageDownload high-quality image (147 K)Download as PowerPoint slide