| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 155003 | Chemical Engineering Science | 2014 | 13 Pages |

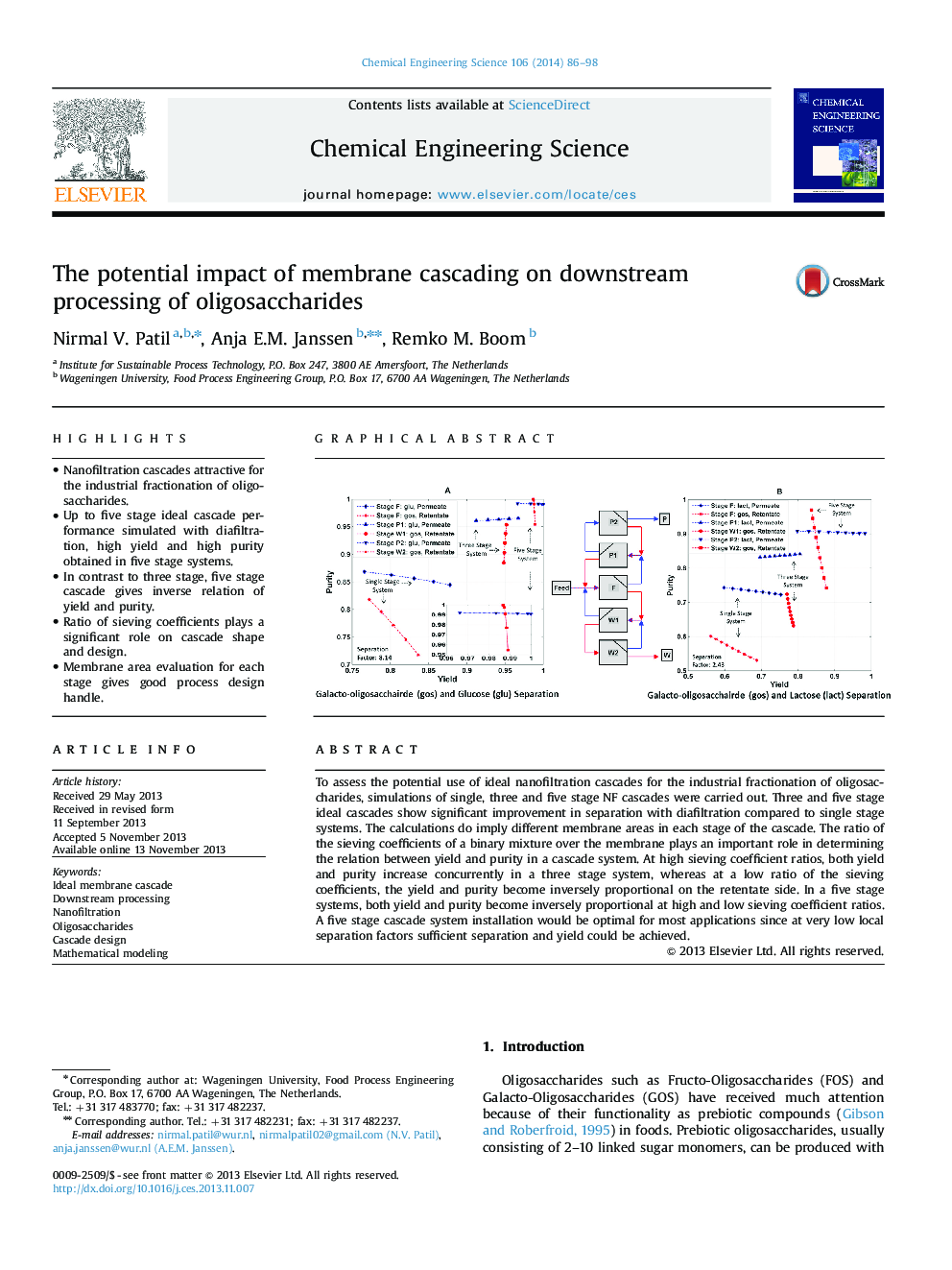

•Nanofiltration cascades attractive for the industrial fractionation of oligosaccharides.•Up to five stage ideal cascade performance simulated with diafiltration, high yield and high purity obtained in five stage systems.•In contrast to three stage, five stage cascade gives inverse relation of yield and purity.•Ratio of sieving coefficients plays a significant role on cascade shape and design.•Membrane area evaluation for each stage gives good process design handle.

To assess the potential use of ideal nanofiltration cascades for the industrial fractionation of oligosaccharides, simulations of single, three and five stage NF cascades were carried out. Three and five stage ideal cascades show significant improvement in separation with diafiltration compared to single stage systems. The calculations do imply different membrane areas in each stage of the cascade. The ratio of the sieving coefficients of a binary mixture over the membrane plays an important role in determining the relation between yield and purity in a cascade system. At high sieving coefficient ratios, both yield and purity increase concurrently in a three stage system, whereas at a low ratio of the sieving coefficients, the yield and purity become inversely proportional on the retentate side. In a five stage systems, both yield and purity become inversely proportional at high and low sieving coefficient ratios. A five stage cascade system installation would be optimal for most applications since at very low local separation factors sufficient separation and yield could be achieved.

Graphical abstractFigure optionsDownload full-size imageDownload high-quality image (260 K)Download as PowerPoint slide