| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1629503 | Journal of Iron and Steel Research, International | 2009 | 5 Pages |

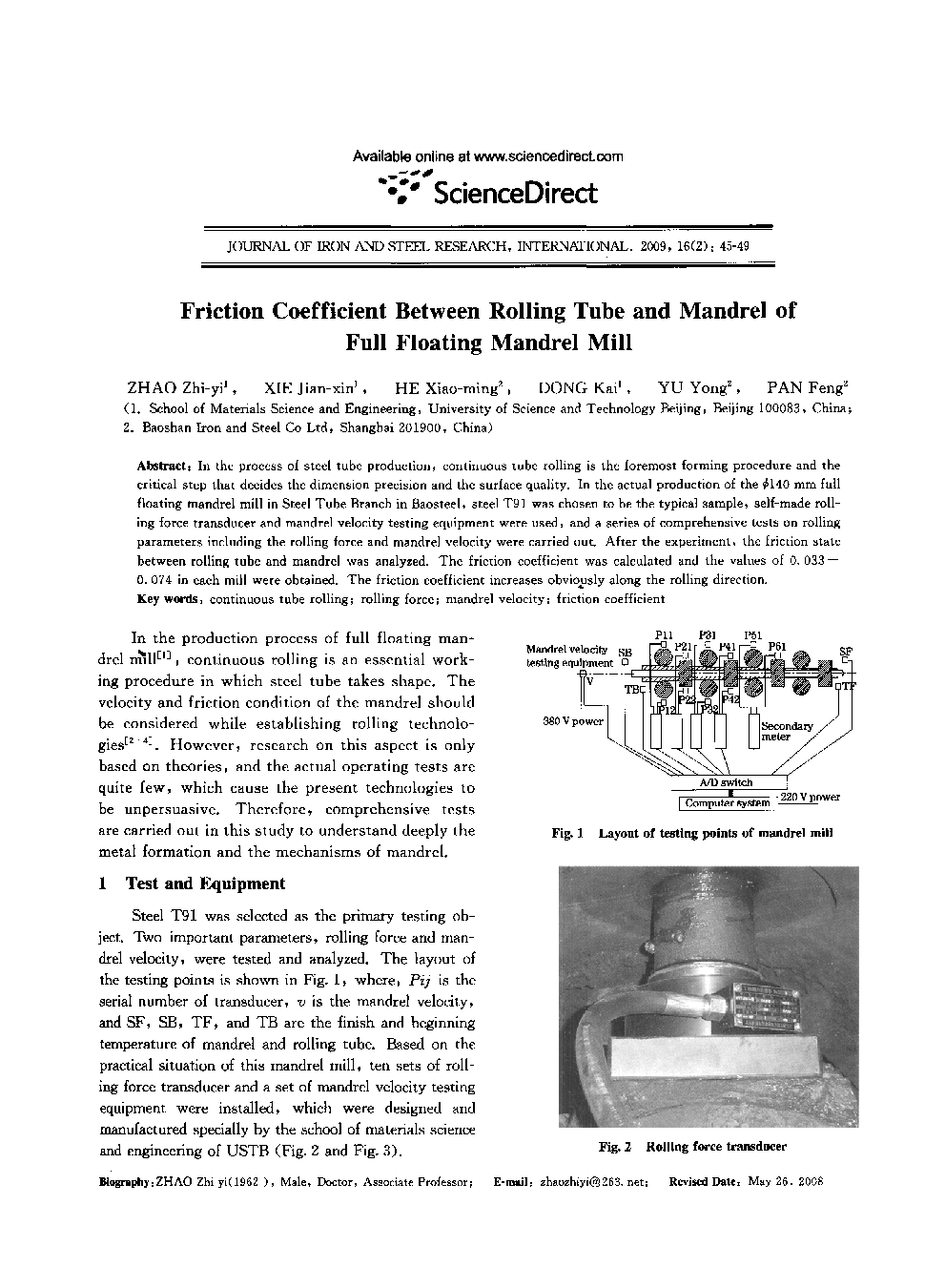

In the process of steel tube production, continuous tube rolling is the foremost forming procedure and the critical step that decides the dimension precision and the surface quality. In the actual production of the ϕ140 mm full floating mandrel mill in Steel Tube Branch in Baosteel, steel T91 was chosen to be the typical sample, self-made rolling force transducer and mandrel velocity testing equipment were used, and a series of comprehensive tests on rolling parameters including the rolling force and mandrel velocity were carried out. After the experiment, the friction state between rolling tube and mandrel was analyzed. The friction coefficient was calculated and the values of 0. 033 − 0. 074 in each mill were obtained. The friction coefficient increases obviously along the rolling direction.