| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1629723 | Journal of Iron and Steel Research, International | 2006 | 5 Pages |

Abstract

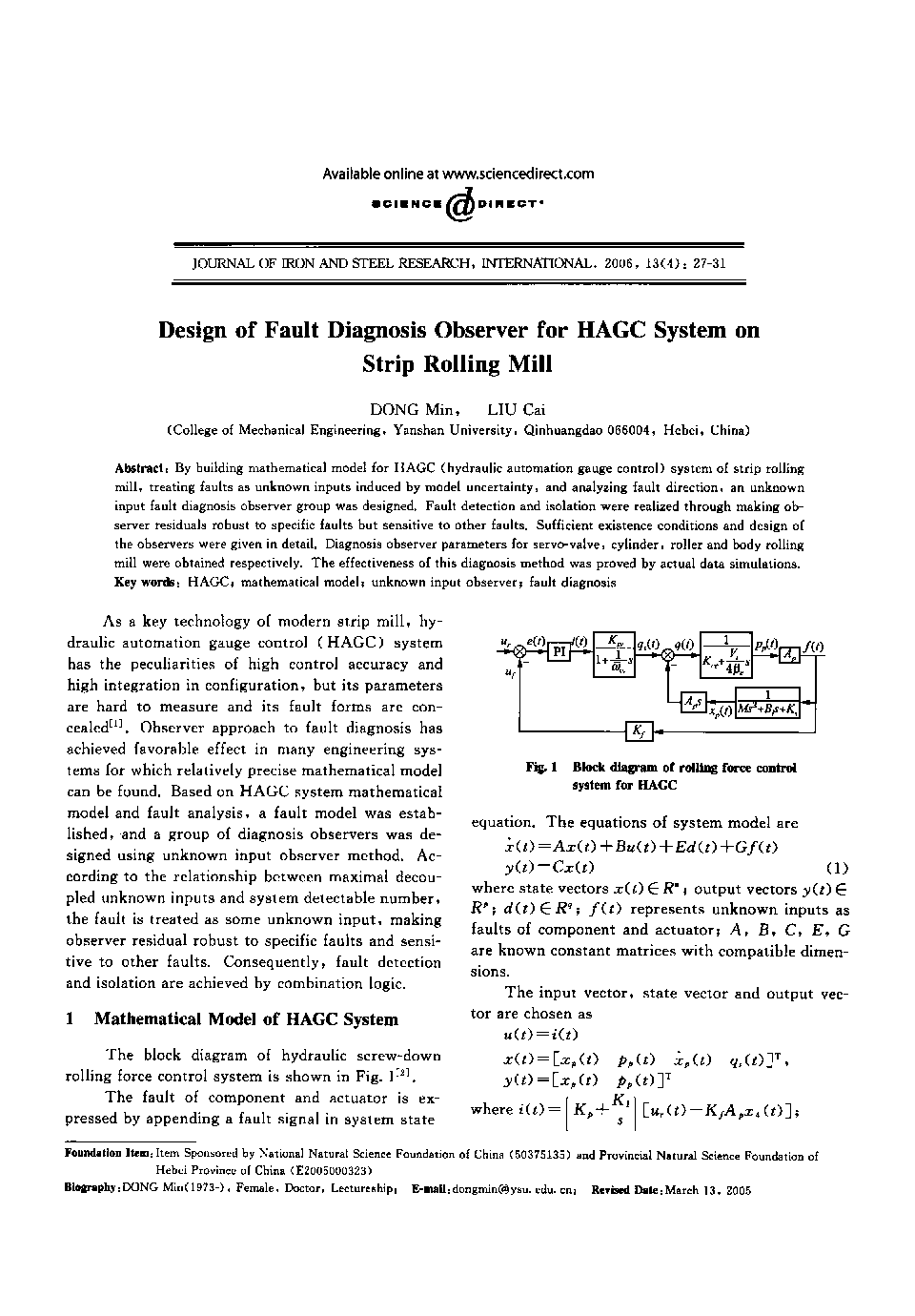

By building mathematical model for HAGC (hydraulic automation gauge control) system of strip rolling mill, treating faults as unknown inputs induced by model uncertainty, and analyzing fault direction, an unknown input fault diagnosis observer group was designed. Fault detection and isolation were realized through making observer residuals robust to specific faults but sensitive to other faults. Sufficient existence conditions and design of the observers were given in detail. Diagnosis observer parameters for servo-vaive, cylinder, roller and body rolling mill were obtained respectively. The effectiveness of this diagnosis method was proved by actual data simulations.

Related Topics

Physical Sciences and Engineering

Materials Science

Metals and Alloys