| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1638683 | Transactions of Nonferrous Metals Society of China | 2011 | 5 Pages |

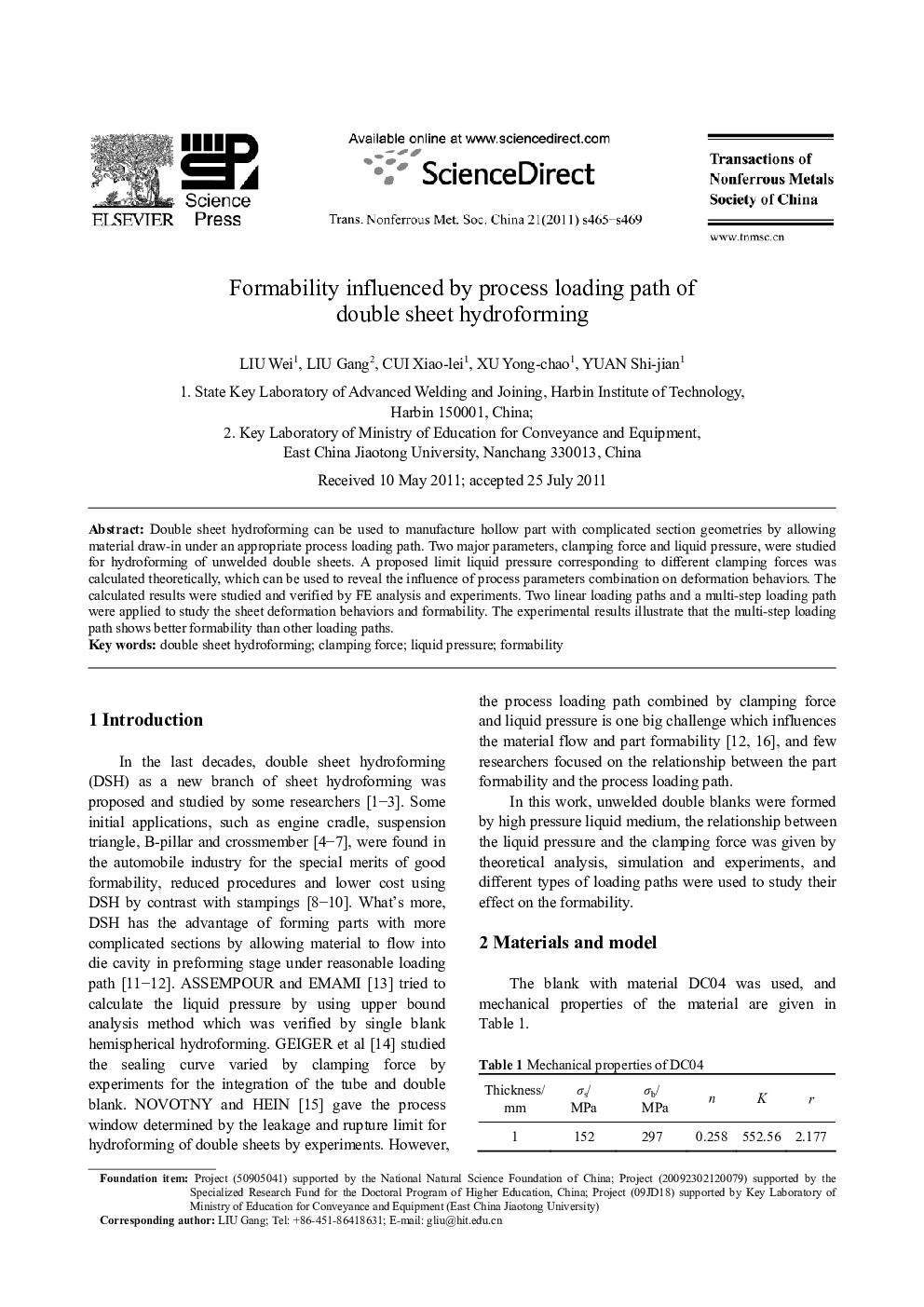

Double sheet hydroforming can be used to manufacture hollow part with complicated section geometries by allowing material draw-in under an appropriate process loading path. Two major parameters, clamping force and liquid pressure, were studied for hydroforming of unwelded double sheets. A proposed limit liquid pressure corresponding to different clamping forces was calculated theoretically, which can be used to reveal the influence of process parameters combination on deformation behaviors. The calculated results were studied and verified by FE analysis and experiments. Two linear loading paths and a multi-step loading path were applied to study the sheet deformation behaviors and formability. The experimental results illustrate that the multi-step loading path shows better formability than other loading paths.