| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1649013 | Materials Letters | 2011 | 4 Pages |

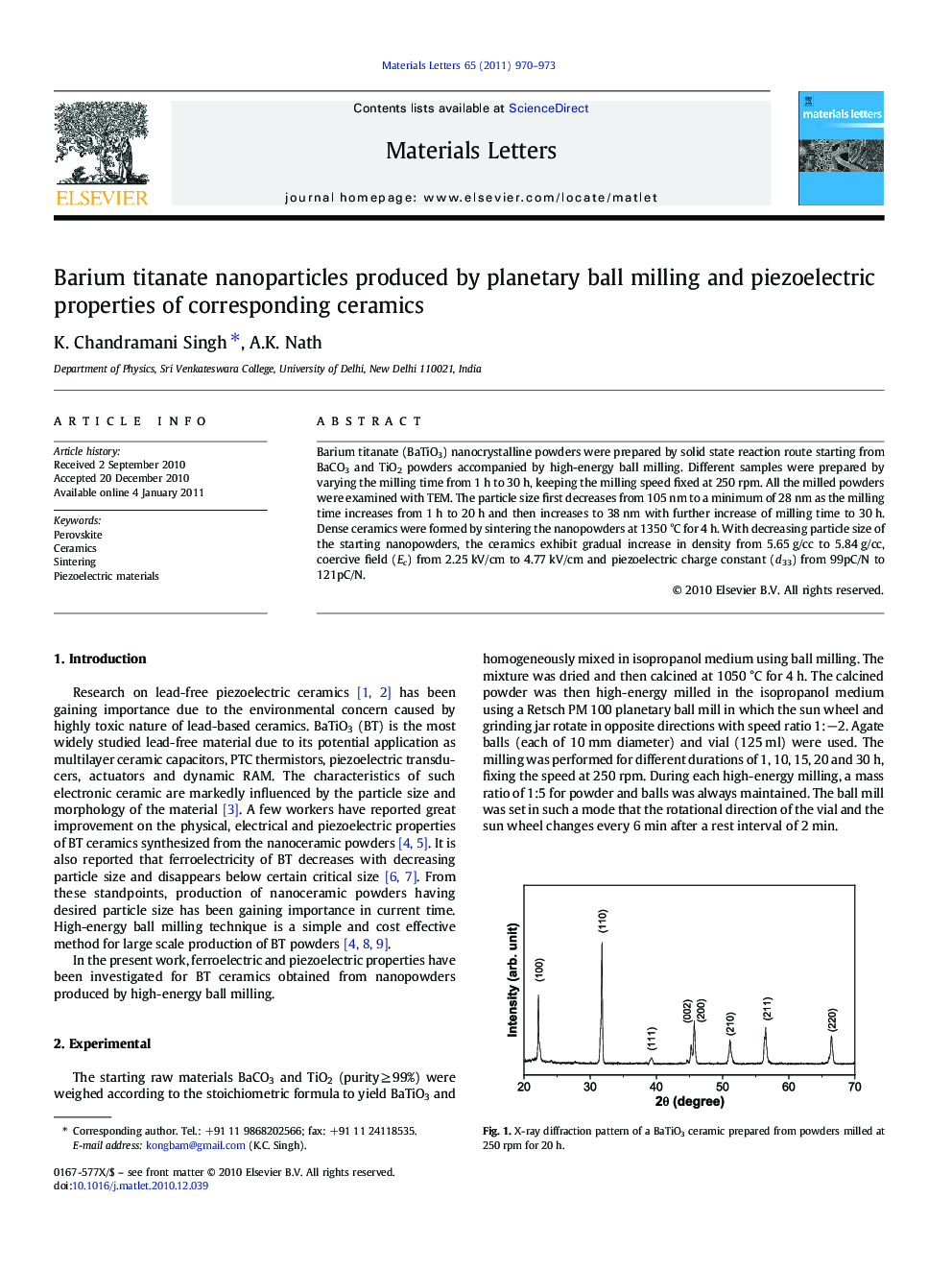

Barium titanate (BaTiO3) nanocrystalline powders were prepared by solid state reaction route starting from BaCO3 and TiO2 powders accompanied by high-energy ball milling. Different samples were prepared by varying the milling time from 1 h to 30 h, keeping the milling speed fixed at 250 rpm. All the milled powders were examined with TEM. The particle size first decreases from 105 nm to a minimum of 28 nm as the milling time increases from 1 h to 20 h and then increases to 38 nm with further increase of milling time to 30 h. Dense ceramics were formed by sintering the nanopowders at 1350 °C for 4 h. With decreasing particle size of the starting nanopowders, the ceramics exhibit gradual increase in density from 5.65 g/cc to 5.84 g/cc, coercive field (Ec) from 2.25 kV/cm to 4.77 kV/cm and piezoelectric charge constant (d33) from 99pC/N to 121pC/N.

Research Highlights► BaTiO3 nanopowders with 105–28 nm particle size were produced by high-energy milling. ► Increasing milling time from 1 h to 20 h reduces the particle size from 105 nm to 28 nm. ► Further increase from 20 h to 30 h increases the particle size from 28 nm to 38 nm. ► Prevailing theories fail to explain the increase in particle size with milling time. ► Changes in Ec and d33 for the resulting ceramics corroborate the observed phenomenon.