| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

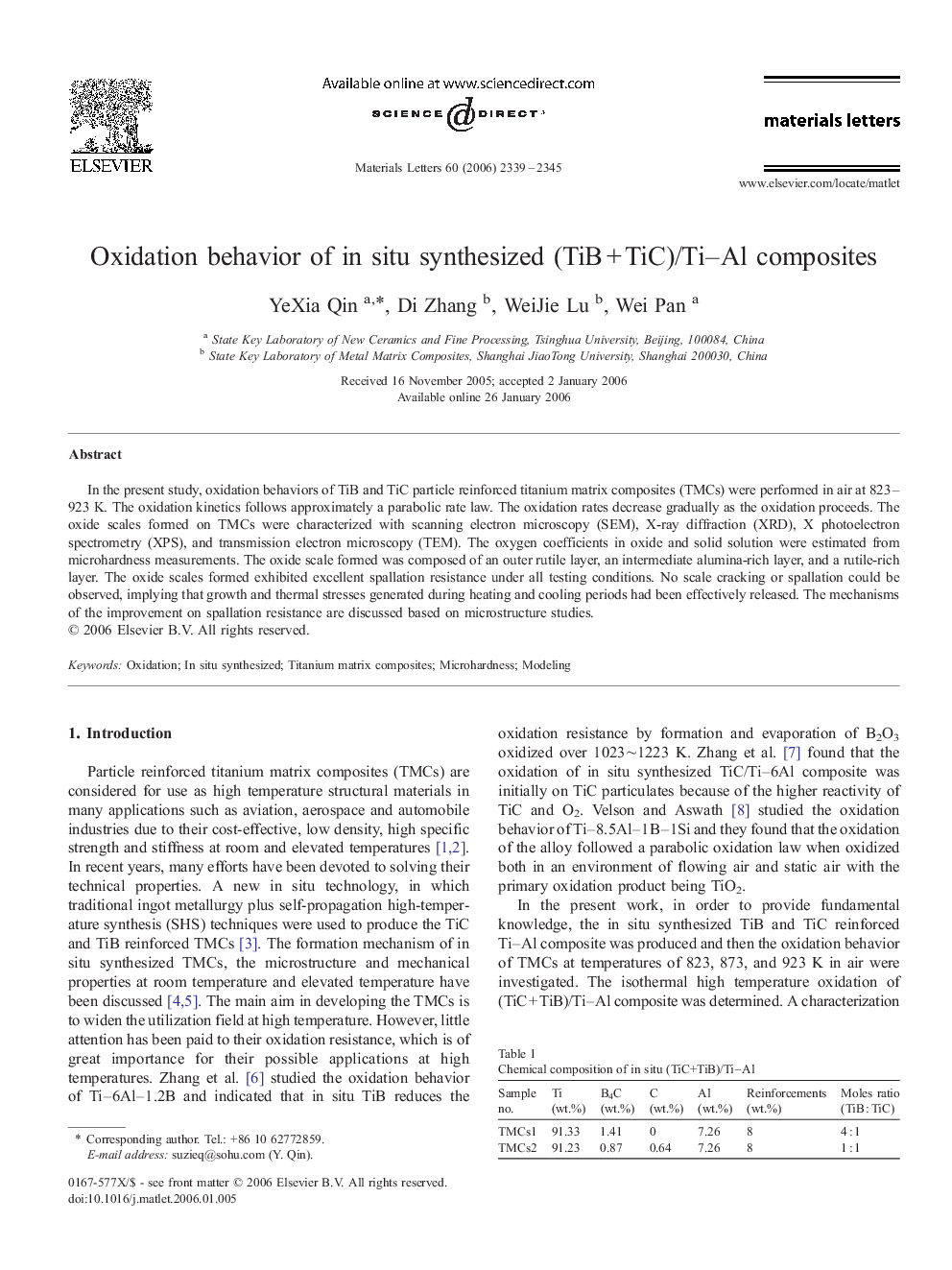

| 1653974 | Materials Letters | 2006 | 7 Pages |

In the present study, oxidation behaviors of TiB and TiC particle reinforced titanium matrix composites (TMCs) were performed in air at 823–923 K. The oxidation kinetics follows approximately a parabolic rate law. The oxidation rates decrease gradually as the oxidation proceeds. The oxide scales formed on TMCs were characterized with scanning electron microscopy (SEM), X-ray diffraction (XRD), X photoelectron spectrometry (XPS), and transmission electron microscopy (TEM). The oxygen coefficients in oxide and solid solution were estimated from microhardness measurements. The oxide scale formed was composed of an outer rutile layer, an intermediate alumina-rich layer, and a rutile-rich layer. The oxide scales formed exhibited excellent spallation resistance under all testing conditions. No scale cracking or spallation could be observed, implying that growth and thermal stresses generated during heating and cooling periods had been effectively released. The mechanisms of the improvement on spallation resistance are discussed based on microstructure studies.