| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1660822 | Surface and Coatings Technology | 2007 | 5 Pages |

Abstract

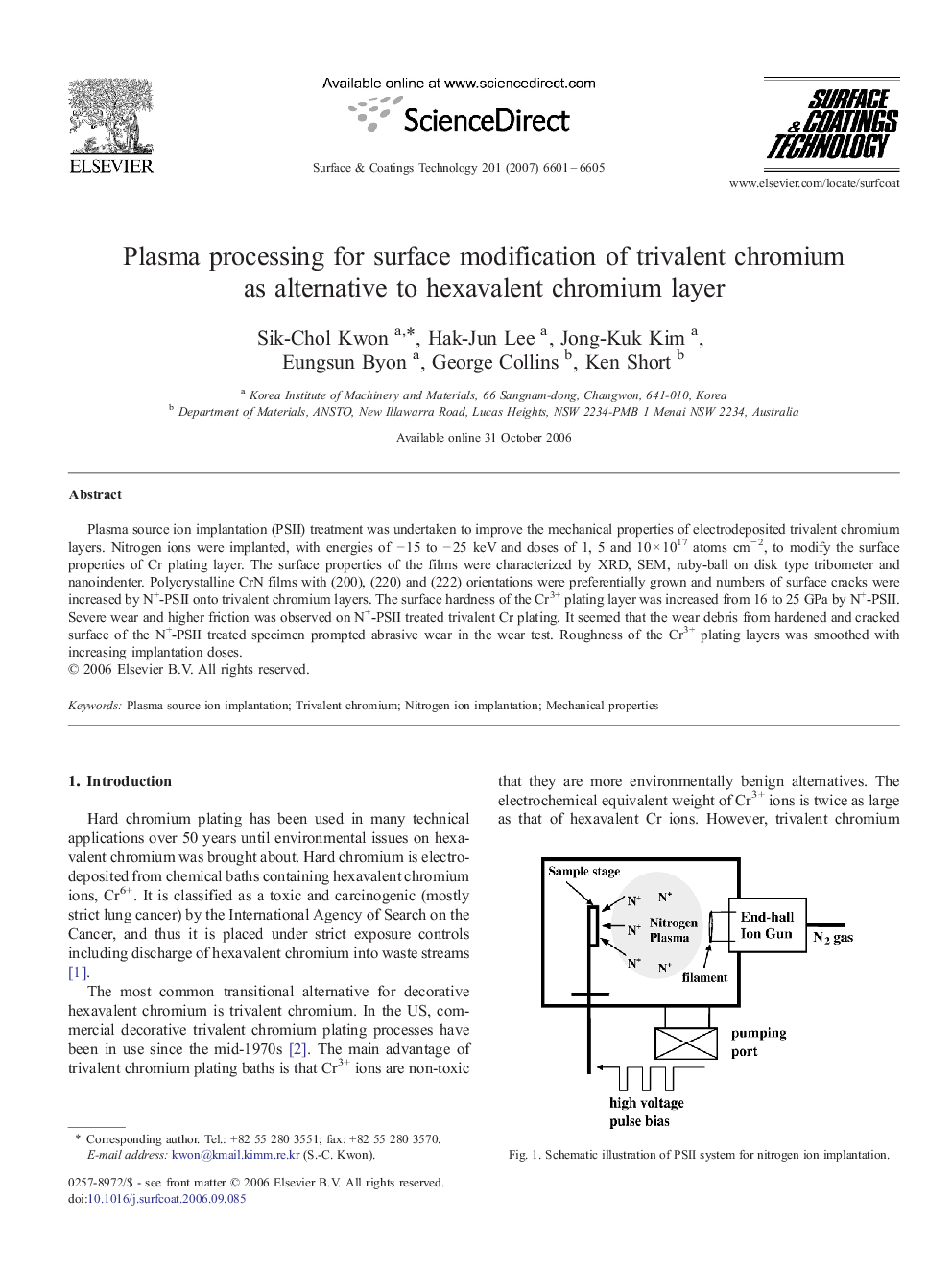

Plasma source ion implantation (PSII) treatment was undertaken to improve the mechanical properties of electrodeposited trivalent chromium layers. Nitrogen ions were implanted, with energies of â 15 to â 25 keV and doses of 1, 5 and 10 Ã 1017 atoms cmâ 2, to modify the surface properties of Cr plating layer. The surface properties of the films were characterized by XRD, SEM, ruby-ball on disk type tribometer and nanoindenter. Polycrystalline CrN films with (200), (220) and (222) orientations were preferentially grown and numbers of surface cracks were increased by N+-PSII onto trivalent chromium layers. The surface hardness of the Cr3+ plating layer was increased from 16 to 25 GPa by N+-PSII. Severe wear and higher friction was observed on N+-PSII treated trivalent Cr plating. It seemed that the wear debris from hardened and cracked surface of the N+-PSII treated specimen prompted abrasive wear in the wear test. Roughness of the Cr3+ plating layers was smoothed with increasing implantation doses.

Keywords

Related Topics

Physical Sciences and Engineering

Materials Science

Nanotechnology

Authors

Sik-Chol Kwon, Hak-Jun Lee, Jong-Kuk Kim, Eungsun Byon, George Collins, Ken Short,