| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1660861 | Surface and Coatings Technology | 2007 | 4 Pages |

Abstract

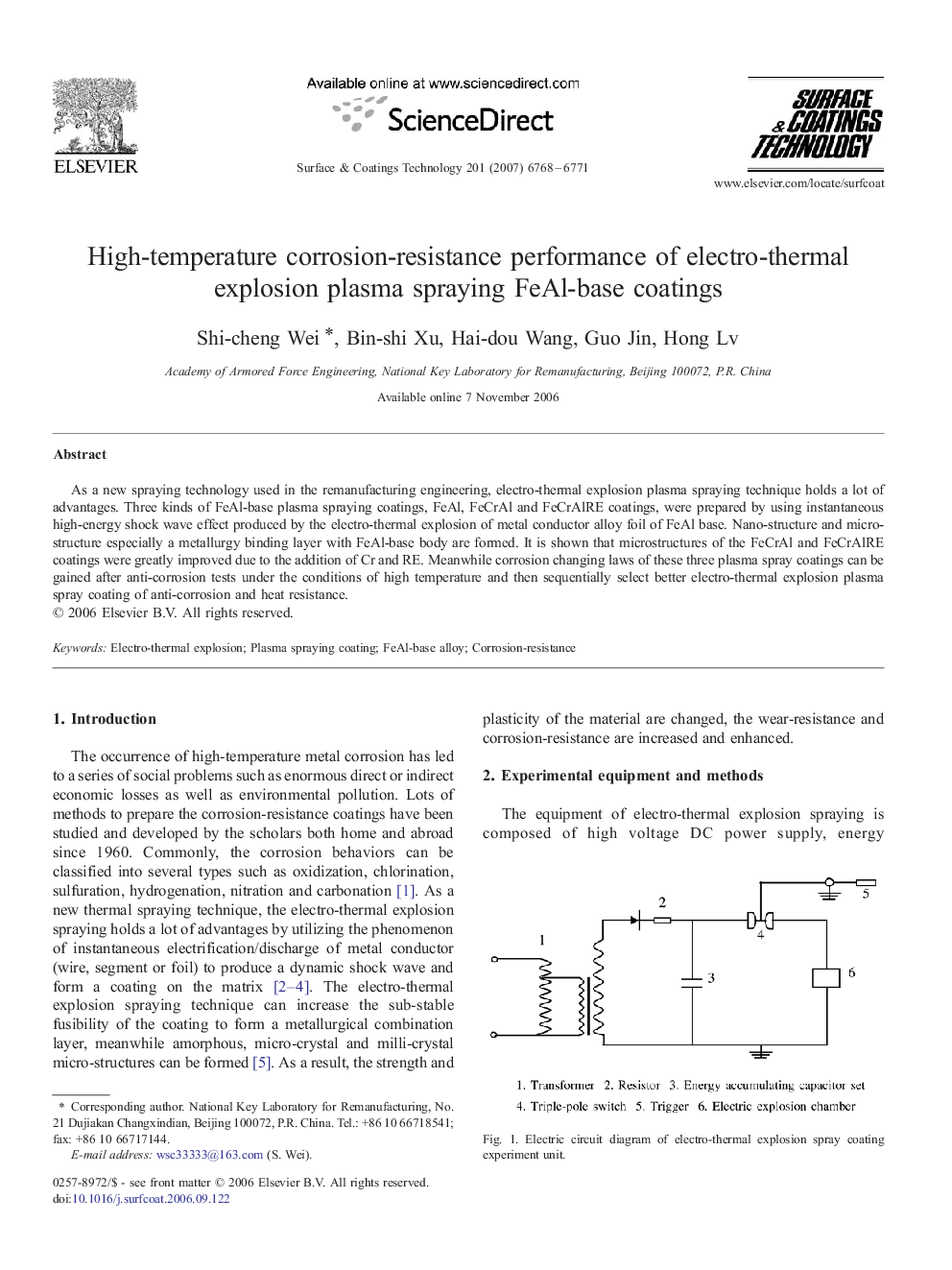

As a new spraying technology used in the remanufacturing engineering, electro-thermal explosion plasma spraying technique holds a lot of advantages. Three kinds of FeAl-base plasma spraying coatings, FeAl, FeCrAl and FeCrAlRE coatings, were prepared by using instantaneous high-energy shock wave effect produced by the electro-thermal explosion of metal conductor alloy foil of FeAl base. Nano-structure and micro-structure especially a metallurgy binding layer with FeAl-base body are formed. It is shown that microstructures of the FeCrAl and FeCrAlRE coatings were greatly improved due to the addition of Cr and RE. Meanwhile corrosion changing laws of these three plasma spray coatings can be gained after anti-corrosion tests under the conditions of high temperature and then sequentially select better electro-thermal explosion plasma spray coating of anti-corrosion and heat resistance.

Keywords

Related Topics

Physical Sciences and Engineering

Materials Science

Nanotechnology

Authors

Shi-cheng Wei, Bin-shi Xu, Hai-dou Wang, Guo Jin, Hong Lv,