| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

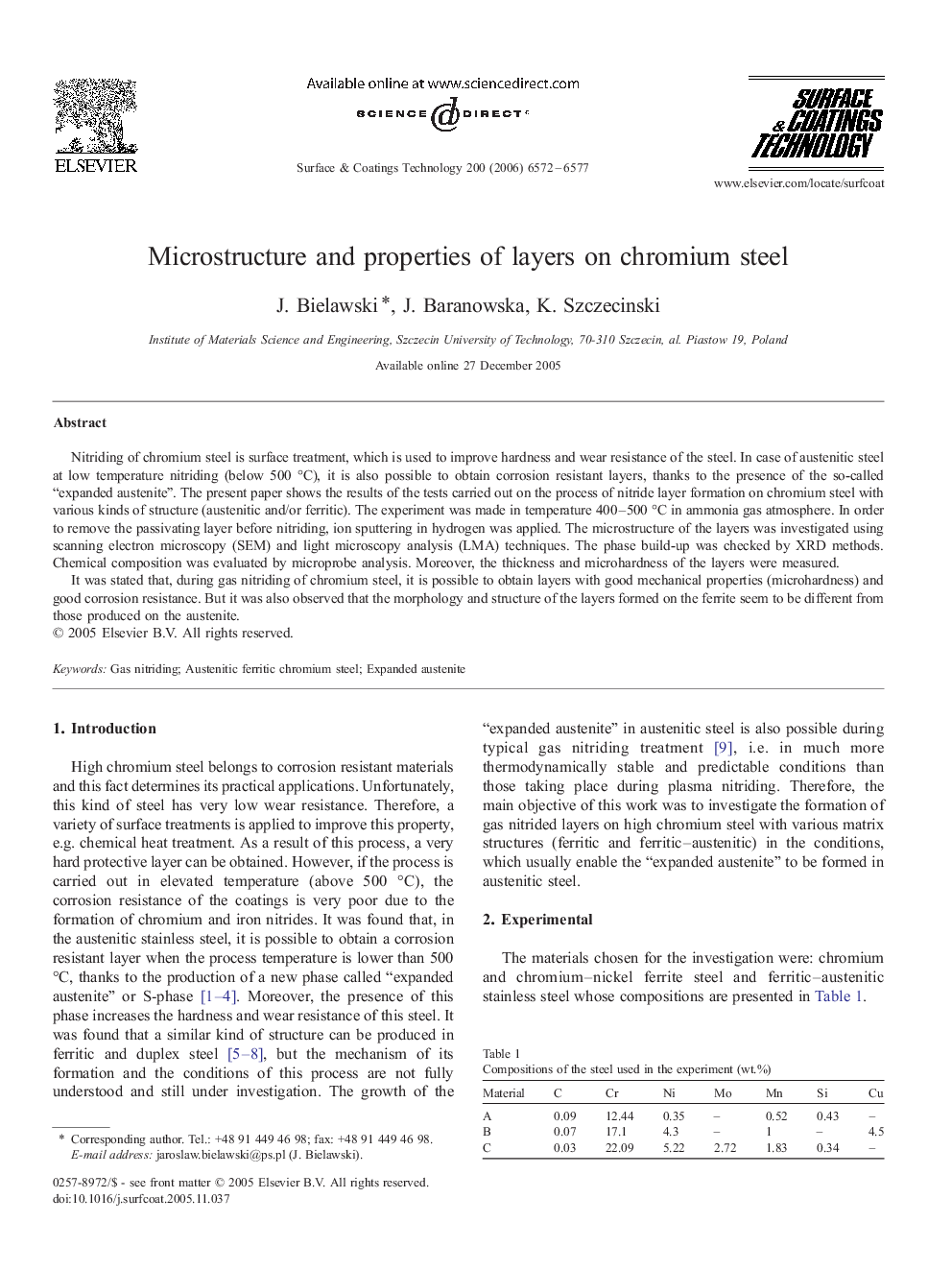

| 1661961 | Surface and Coatings Technology | 2006 | 6 Pages |

Nitriding of chromium steel is surface treatment, which is used to improve hardness and wear resistance of the steel. In case of austenitic steel at low temperature nitriding (below 500 °C), it is also possible to obtain corrosion resistant layers, thanks to the presence of the so-called “expanded austenite”. The present paper shows the results of the tests carried out on the process of nitride layer formation on chromium steel with various kinds of structure (austenitic and/or ferritic). The experiment was made in temperature 400–500 °C in ammonia gas atmosphere. In order to remove the passivating layer before nitriding, ion sputtering in hydrogen was applied. The microstructure of the layers was investigated using scanning electron microscopy (SEM) and light microscopy analysis (LMA) techniques. The phase build-up was checked by XRD methods. Chemical composition was evaluated by microprobe analysis. Moreover, the thickness and microhardness of the layers were measured.It was stated that, during gas nitriding of chromium steel, it is possible to obtain layers with good mechanical properties (microhardness) and good corrosion resistance. But it was also observed that the morphology and structure of the layers formed on the ferrite seem to be different from those produced on the austenite.