| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1661993 | Surface and Coatings Technology | 2007 | 8 Pages |

Abstract

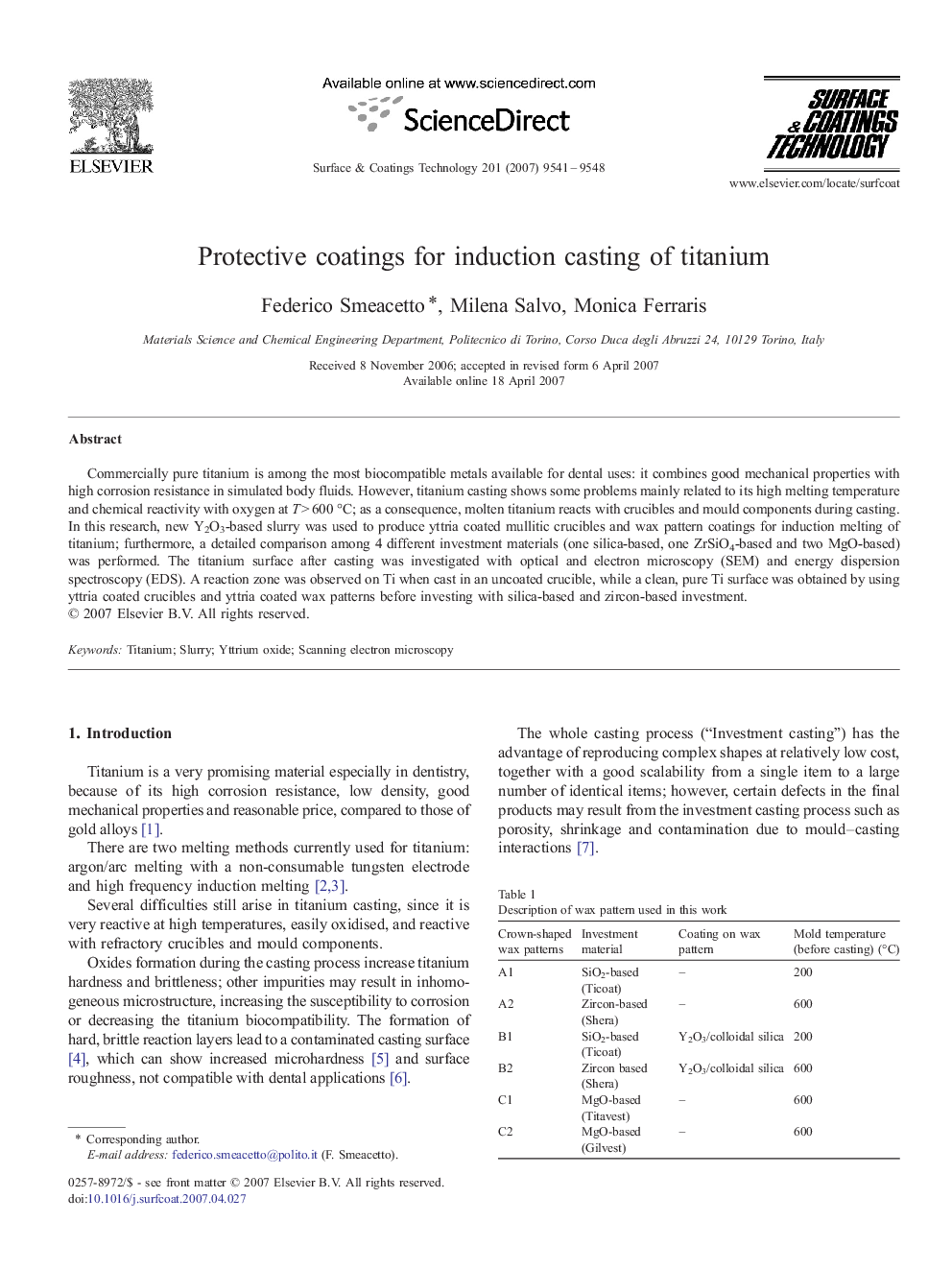

Commercially pure titanium is among the most biocompatible metals available for dental uses: it combines good mechanical properties with high corrosion resistance in simulated body fluids. However, titanium casting shows some problems mainly related to its high melting temperature and chemical reactivity with oxygen at T > 600 °C; as a consequence, molten titanium reacts with crucibles and mould components during casting. In this research, new Y2O3-based slurry was used to produce yttria coated mullitic crucibles and wax pattern coatings for induction melting of titanium; furthermore, a detailed comparison among 4 different investment materials (one silica-based, one ZrSiO4-based and two MgO-based) was performed. The titanium surface after casting was investigated with optical and electron microscopy (SEM) and energy dispersion spectroscopy (EDS). A reaction zone was observed on Ti when cast in an uncoated crucible, while a clean, pure Ti surface was obtained by using yttria coated crucibles and yttria coated wax patterns before investing with silica-based and zircon-based investment.

Related Topics

Physical Sciences and Engineering

Materials Science

Nanotechnology

Authors

Federico Smeacetto, Milena Salvo, Monica Ferraris,