| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1662528 | Surface and Coatings Technology | 2006 | 7 Pages |

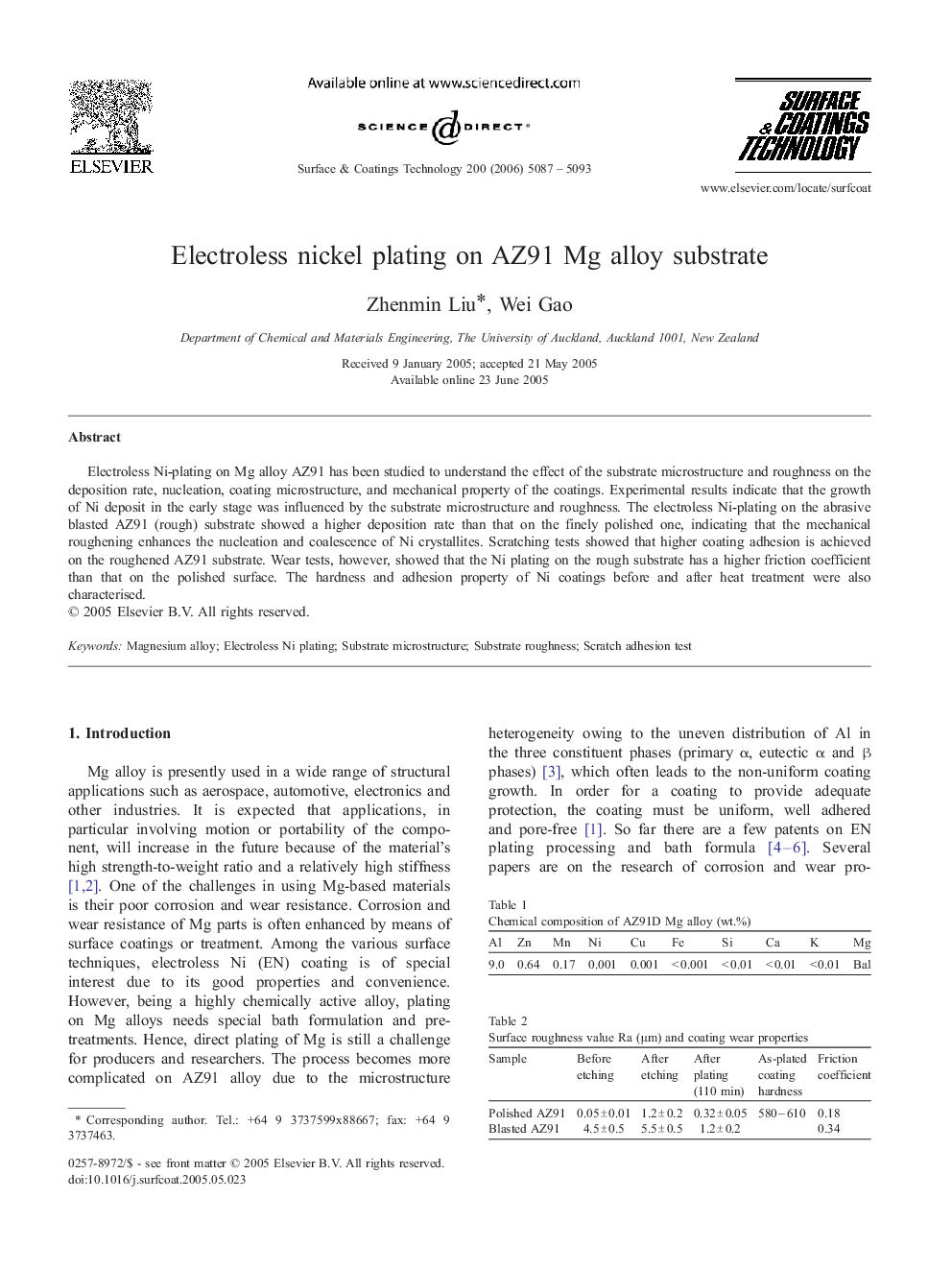

Electroless Ni-plating on Mg alloy AZ91 has been studied to understand the effect of the substrate microstructure and roughness on the deposition rate, nucleation, coating microstructure, and mechanical property of the coatings. Experimental results indicate that the growth of Ni deposit in the early stage was influenced by the substrate microstructure and roughness. The electroless Ni-plating on the abrasive blasted AZ91 (rough) substrate showed a higher deposition rate than that on the finely polished one, indicating that the mechanical roughening enhances the nucleation and coalescence of Ni crystallites. Scratching tests showed that higher coating adhesion is achieved on the roughened AZ91 substrate. Wear tests, however, showed that the Ni plating on the rough substrate has a higher friction coefficient than that on the polished surface. The hardness and adhesion property of Ni coatings before and after heat treatment were also characterised.