| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1663348 | Surface and Coatings Technology | 2006 | 5 Pages |

Abstract

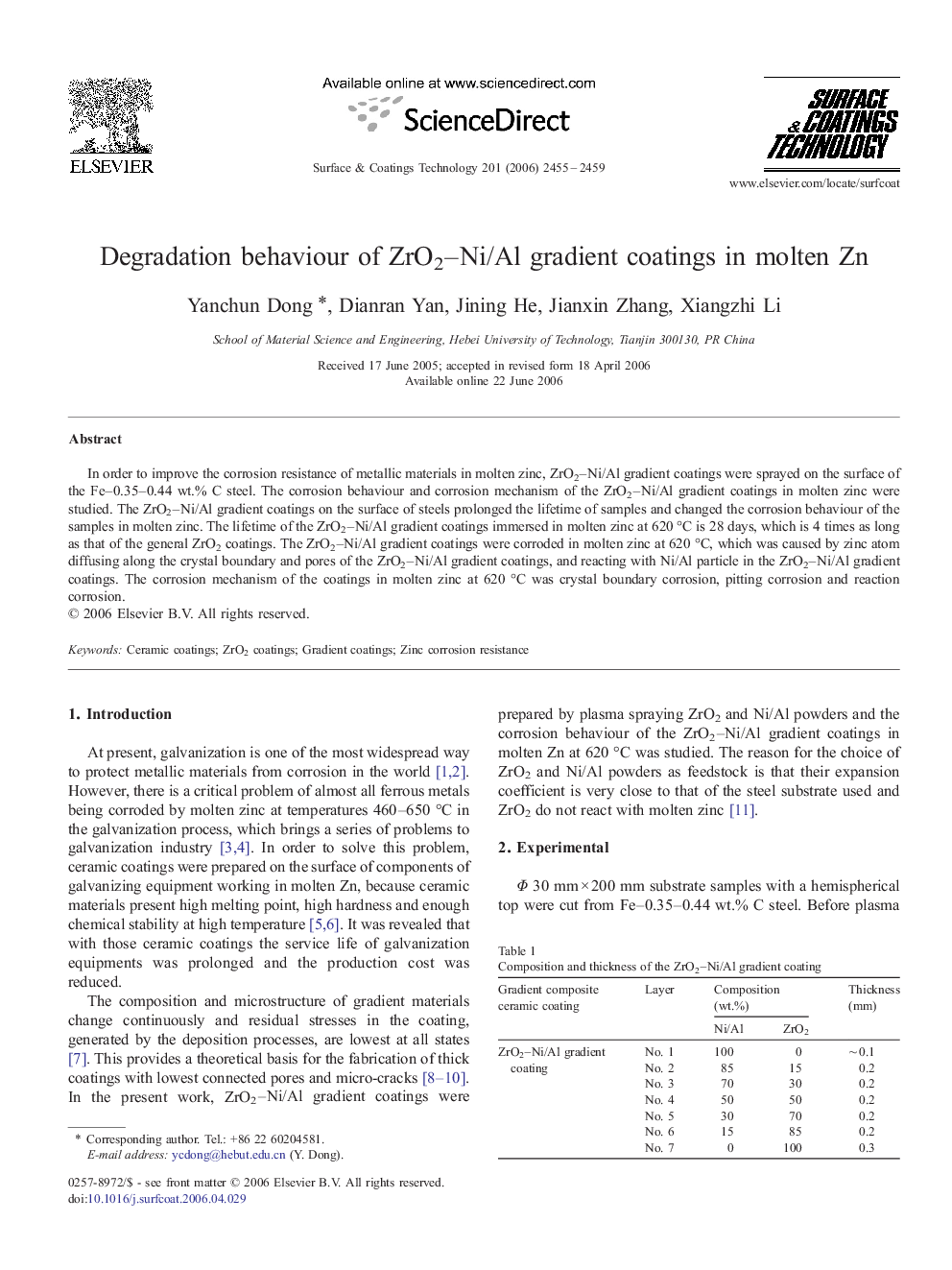

In order to improve the corrosion resistance of metallic materials in molten zinc, ZrO2-Ni/Al gradient coatings were sprayed on the surface of the Fe-0.35-0.44 wt.% C steel. The corrosion behaviour and corrosion mechanism of the ZrO2-Ni/Al gradient coatings in molten zinc were studied. The ZrO2-Ni/Al gradient coatings on the surface of steels prolonged the lifetime of samples and changed the corrosion behaviour of the samples in molten zinc. The lifetime of the ZrO2-Ni/Al gradient coatings immersed in molten zinc at 620 °C is 28 days, which is 4 times as long as that of the general ZrO2 coatings. The ZrO2-Ni/Al gradient coatings were corroded in molten zinc at 620 °C, which was caused by zinc atom diffusing along the crystal boundary and pores of the ZrO2-Ni/Al gradient coatings, and reacting with Ni/Al particle in the ZrO2-Ni/Al gradient coatings. The corrosion mechanism of the coatings in molten zinc at 620 °C was crystal boundary corrosion, pitting corrosion and reaction corrosion.

Related Topics

Physical Sciences and Engineering

Materials Science

Nanotechnology

Authors

Yanchun Dong, Dianran Yan, Jining He, Jianxin Zhang, Xiangzhi Li,