| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1676674 | Thin Solid Films | 2006 | 5 Pages |

Abstract

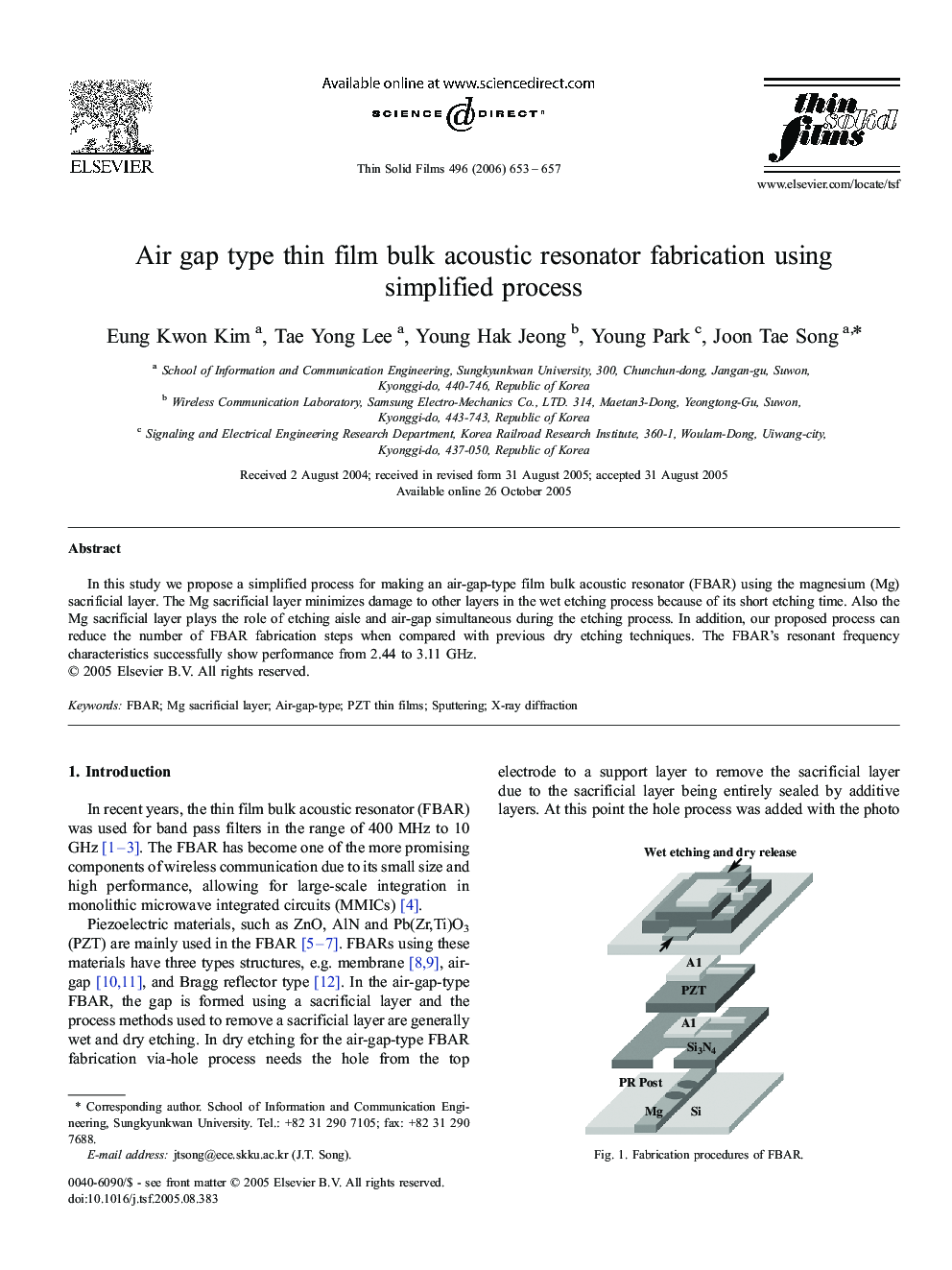

In this study we propose a simplified process for making an air-gap-type film bulk acoustic resonator (FBAR) using the magnesium (Mg) sacrificial layer. The Mg sacrificial layer minimizes damage to other layers in the wet etching process because of its short etching time. Also the Mg sacrificial layer plays the role of etching aisle and air-gap simultaneous during the etching process. In addition, our proposed process can reduce the number of FBAR fabrication steps when compared with previous dry etching techniques. The FBAR's resonant frequency characteristics successfully show performance from 2.44 to 3.11 GHz.

Related Topics

Physical Sciences and Engineering

Materials Science

Nanotechnology

Authors

Eung Kwon Kim, Tae Yong Lee, Young Hak Jeong, Young Park, Joon Tae Song,